E-pos: [email protected]

Warmverkoopstoerusting vir vergruis en slypverwerking vir kwarts

Quartz is a mineral that is particularly useful in many industries including glass, ceramics and electronics. Picking the right crushing and grinding processing equipment for quartz is a critical step in the manufacture of many items.

Jaw crushers, impakbrekers, kegelbrekers, hammer mills, and ball mills are common pieces of quartz crushing and grinding equipment. The role of kaakbrekers is to break large rocks into smaller debris, while impact crushers and cone crushers can be secondary crushing. For grinding we often use hammer mills and ball mills.

The sand mill is also popular with customers to get fine size and high quality sand in the sand production process because quartz crusher plants can crush quartz particles from 10mm to 40mm.

Sand and quartz stone are ground together to create quartz sand. The jaw crusher serves as the primary crushing device in the quartz sand production line, followed by the impact crusher for fine grinding and the sand maker (vsi5x crusher) for producing sand and stone. We use vibrating screens as screening equipment to screen suitable sand.

Quartz crusher usually crush kwarts into particles from 10mm to 40mm for construction such as highways, highways and railways. Sometimes, we often use quartz crushers in gold mining projects to crush granite, marmer, kwarts, ens. in gold ore.

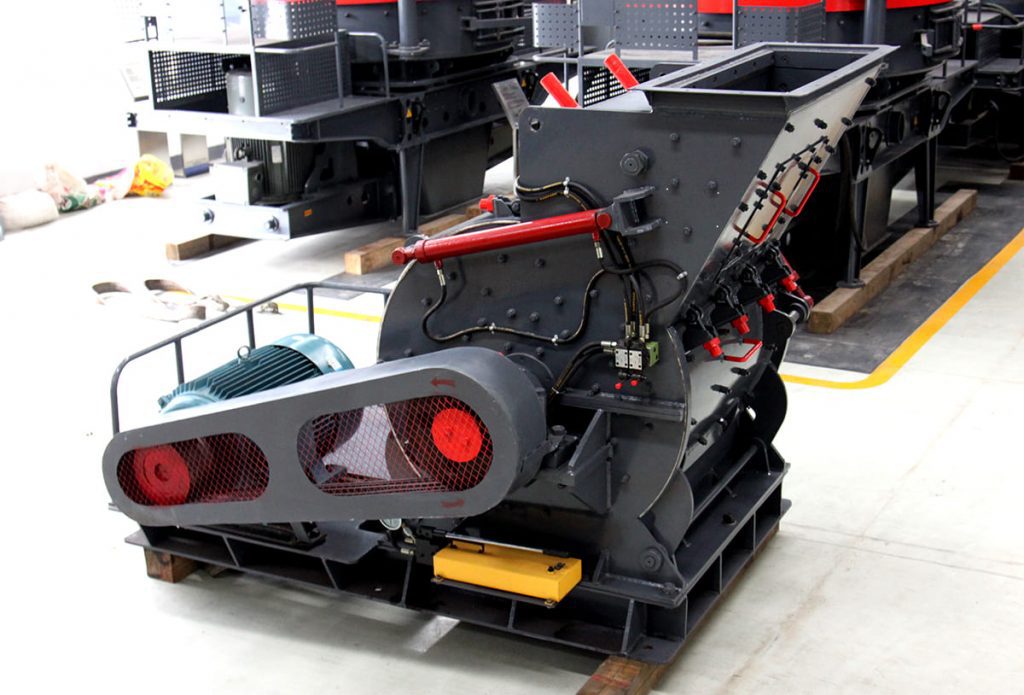

Crushing Processing Equipment For Quartz

There are several types of machines in the quartz sand production line. The main machine is quartz crushing equipment.

Jaw crusher for quartz. The function of jaw crusher is to crush materials and grade granite, marmer, gold ore and quartz. Jaw crusher has the following advantages: simple structure and reliable operation, easy maintenance and low cost of operation.

Quartz Sand Impact Crusher: An impact crusher for fine crushing of quartz used in quartz crushing complex. The most obvious advantage is the excellent function overhaul. Quartz impact crusher is suitable for producing high quality crusher for highway, energy and building materials industries.

VSI crusher for quartz sand: Another name for a VSI breker is a sand making machine. The action process of VSI crusher is fine crushing and coarse grinding of gravel, kwarts, basalt, sandstone, silicon carbide and sintered bauxite.

The quartz raw material enters the jaw crusher for primary crushing, and the crushed material enters the cone crusher or impact crusher through the belt conveyor for secondary crushing. After secondary crushing, the quartz stone passes through the vibrating screen to separate the required particle size.

Grinding Processing Equipment For Quartz

In the sand making process, usually the sand mill is also popular with customers, in order to get fine size and high quality sand.

Quartz Sand Hammer Mill: The hammer mill is mainly used to grind coarse powder and produce fine sand. And its output size of 0-3mm can reach more than 90%.

The quartz is crushed into small particles before being ground in a ball mill or hammer mill during the grinding process. A classifier separates the ground material, and the coarse particles are returned to the mill for further grinding.

Ten slotte

It is critical to select the right crushing and grinding processing equipment for the unique properties of the quartz being processed, such as hardness, grootte, and shape. Proper equipment selection can boost efficiency and reduce energy usage, leading to cost savings and enhanced output.