E-pos: [email protected]

Jaw Crusher Applications in Agricultural Limestone Processing

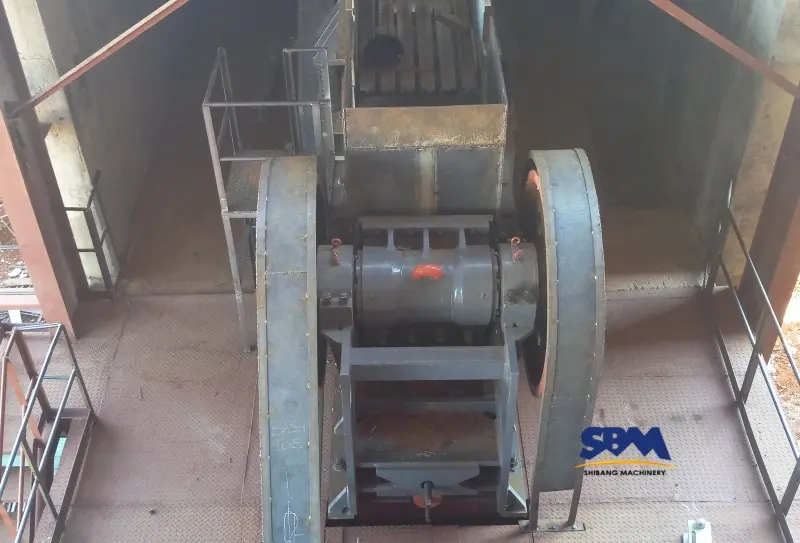

From Midwest prairies to Southeast Asian paddies, crushed limestone breathes life into acidic farmland—but unlocking its full potential demands jaw crushers engineered to tackle regional rock formations, balancing power with precision. Enter jaw crusher—versatile machines designed to break down large limestone rocks into uniform particles ideal for agricultural use.

Why Jaw Crushers Excel in Agricultural Limestone Processing?

Precision and Versatility

Jaw crusher delivers consistent particle sizes, crucial for even soil distribution. With a twist of hydraulic toggles, operators dial-in limestone granularity—from powder that dissolves in morning dew to pea-sized chunks for slow-release. This dust-defying design outperforms hammer mills’ choking clouds, keeping both lungs and profit margins intact during 16-hour harvest prep marathons.

Durability for Heavy-Duty Applications

Forged for relentless limestone grinding, jaw crusher armored with manganese alloy jaws thrive in round-the-clock farming operations—where equipment failure means lost harvests.

Gevallestudie: Enhancing Soil Health in Australia’s Wheat Belt

In New South Wales, Australia, a 2,500-acre wheat farm struggled with acidic soil (pH 4.9). After adopting a jaw crusher to process locally sourced limestone, the farm achieved:

- 20% faster limestone preparation compared to traditional methods.

- Soil pH balanced to 6.3 within 8 months.

- A 15% increase in wheat yield over two growing seasons.

“The jaw crusher allowed us to control particle size precisely, maximizing agricultural limestone absorption,” noted farm manager Liam Carter.

Key Features of an Effective Agricultural Limestone Crusher

1. Adjustable Output Settings

Look for crushers with hydraulic toggle systems to easily modify output size—from 10mm (ideal for rapid soil absorption) to 30mm granules for slow-release applications.

2. Fuel or Electric Power Options

Remote farms benefit from diesel-powered kaakbrekers, while grid-connected operations might prefer electric models for lower emissions.

3. Low Maintenance Design

Sealed bearings and easily replaceable wear parts reduce downtime. Regular lubrication and belt inspections can extend a crusher’s lifespan by up to 50%.

Sustainable Benefits of Jaw Crusher in Agriculture

Reducing Waste and Costs

By processing on-site, farmers cut transportation expenses and limestone waste. A U.S. study showed Kansas farms saved $18/ton using mobile jaw crushers versus purchasing pre-crushed limestone.

Environmental Impact

Precise crushing minimizes over-application, preventing limestone runoff into waterways. This supports compliance with regulations like the EU’s Water Framework Directive.

Pro Tips for Maintaining Your Jaw Crusher

- Weekly Checks: Inspect jaw plates for uneven wear and rotate them if needed.

- Smeer: Use high-temperature grease for bearings to handle limestone’s abrasive nature.

- Safety First: Always isolate power before clearing blockages.

Smart Investment for Long-Term Soil Health

Think of jaw crushers as a field engineer’s secret weapon—crushing limestone at the source slashes transport costs while locking minerals into soil structure. In Tuscany’s sun-drenched vineyards or Brazil’s soybean heartland, growers tracking 20-year soil pH maps swear by their crusher’s gear-driven durability to outlast market cycles.

Hoofkwartierkantoor

Whatsapp:+8615225176731

E-pos: [email protected]

Adres: Geen. 1688, Gaoke East Road, Pudong nuwe distrik, Sjanghai, Sjina.

Webwerf: https://www.mill-sbm.com/

Artikelinhoud

Onlangse plasings

- Jaw Crusher Applications in Agricultural Limestone ProcessingFrom Midwest prairies to Southeast Asian paddies, crushed limestone breathes life into acidic farmland—but unlocking its full potential demands jaw crushers engineered to tackle regional rock formations, balancing power with…

- Gold Ore Processing: Jaw Crusher EfficiencyEffective gold ore processing hinges on precise crushing operations, where jaw crushers convert rugged deposits into optimized feedstock. Discover how to fine-tune these machines for peak productivity without compromising worksite…

- Crushing River Gravel with Jaw CrushersA cornerstone of modern construction, river gravel delivers unmatched toughness and adaptability for roads, concrete, and erosion control. Yet its rugged, irregular nature demands machinery built to endure—enter jaw crushers.…