Email: [email protected]

How Jaw Crusher Design Enhances Operational Efficiency in Mining and Construction

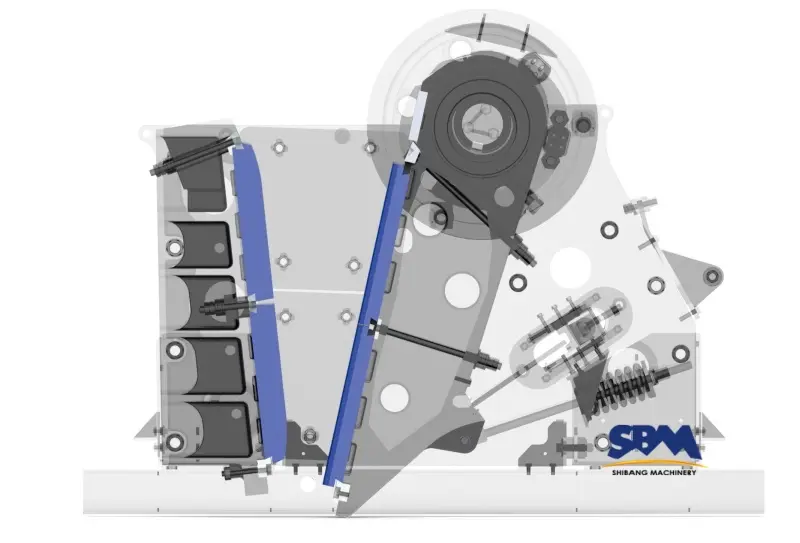

The efficiency of a jaw crusher depends on its design. These design principles maximize production while minimizing energy consumption and downtime. Below, we analyze which key design features contribute to its efficiency, combined with global case studies and technical insights.

1. Structural Innovations: The Backbone of Crushing Performance

New jaw crusher, such as the C6X jaw crusher, features advanced structural designs to optimize force distribution and durability. Key elements include:

- V-Shaped Crushing Chambers: This design widens the feed inlet, allowing larger raw materials (e.g., up to 1,200mm in models like the C6X200 series) to enter without pre-screening. The geometry ensures progressive compression, reducing wear on jaw plates and boosting throughput by 15–20% compared to traditional chambers.

- Reinforced Components: High-quality cast steel for moving jaws and forged eccentric shafts (as seen in European jaw crushers) enhance load-bearing capacity, critical for processing hard materials like scheelite or gold ore in gold mine crusher operations.

Case Study: A Swedish iron ore mine reported a 25% increase in productivity after upgrading to a crusher with a V-shaped chamber and hydraulic discharge adjustments.

2. Adjustability and Automation: Precision in Output Control

Efficiency isn’t just about power—it’s about adaptability. Jaw crushers now integrate:

- Hydraulic Wedge Systems: Replacing manual shim adjustments, these systems enable real-time modifications to the discharge opening. This flexibility ensures consistent product sizing, vital for meeting fixed jaw crusher capacity requirements in aggregate production.

- Centralized Lubrication: Automated lubrication reduces maintenance downtime by 30%, as observed in Australian copper mining operations using SBM crusher models.

3. Material Science and Wear Resistance

The longevity of components directly impacts operational costs. Innovations include:

- Reversible Jaw Plates: Made from BTMcr20 alloy, these plates extend service life by 40% in abrasive environments like scheelite processing plants.

- Toothed Guard Plates: These increase the effective length of jaw plates, improving crushing force distribution and reducing energy consumption per ton.

Case Study: A Canadian limestone quarry reduced replacement costs by 50% after switching to crushers with reversible jaw plates and integrated wear monitoring.

4. Safety and Energy Efficiency: Balancing Power and Protection

Modern designs prioritize both operator safety and sustainability:

- Overload Protection: Sensors and hydraulic systems automatically halt operations during jams, preventing equipment damage. This feature is critical in high-capacity SBM crusher units used in South African platinum mines1.

- Eco-Friendly Motors: Energy-efficient motors reduce power consumption by up to 20%, aligning with global carbon reduction goals.

5. Global Applications: Design Tailored to Local Needs

Jaw crusher efficiency varies by application. For instance:

- Gold Ore Processing: In Ghana, crushers with hermetic structures minimize dust contamination during primary crushing, ensuring sample accuracy.

- Scheelite Crusher Solutions: German tungsten processors favor crushers with adjustable discharge ranges (3–38mm) to accommodate varying mineral hardness.

From hydraulic adjustments to wear-resistant alloys, jaw crusher design is a symphony of engineering aimed at maximizing efficiency. Whether optimizing fixed jaw crusher capacity for urban construction projects or tailoring scheelite crusher configurations for mineral processing, these innovations ensure reliability across industries. For specialized needs, explore models like the C6X jaw crusher or consult global suppliers like SBM crusher to match design with demand.

Headquaters Office

Whatsapp:+8615225176731

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Website: https://www.mill-sbm.com/

Article Contents

Recent Posts

- What are the causes of damage to the jaw crusher plate?Because it is under tremendous pressure during material processing, there are many causes for the damage of the jaw crusher plate. Understanding why they degrade prematurely can save costs and…

- What is the ideal jaw crusher for granite crushing?Granite’s relentless toughness demands jaw crusher built to endure—think armored jaws and unyielding frames. Prioritize crushers that combine brute force with precision engineering, like heat-treated alloys and adaptive crushing chambers.…

- Jaw Crusher for Limestone Processing: A Guide to EfficiencyAs limestone is widely used in construction and industry, its processing requires strong and durable jaw crusher to meet the needs of the industry. Among the many crushers, the jaw…