Email: [email protected]

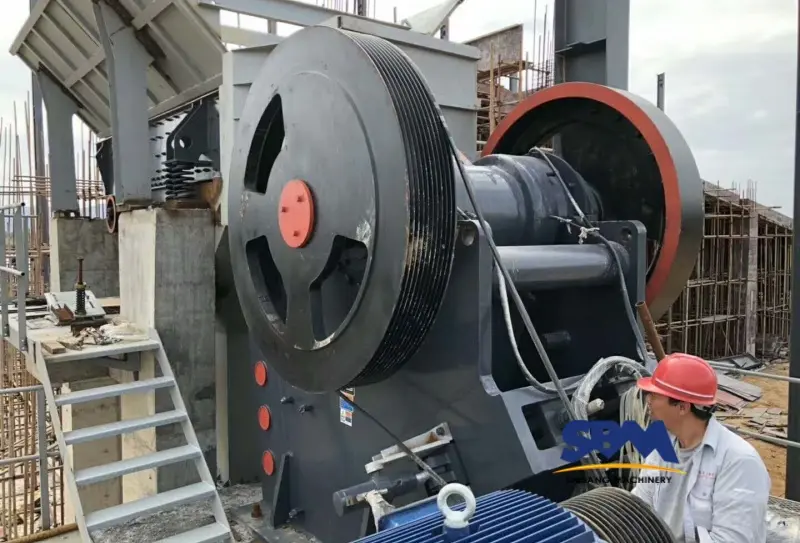

Maintenance Tips for Jaw Crushers: Prolong Lifespan and Boost Efficiency

Proper maintenance is the cornerstone of maximizing the performance and longevity of your jaw crusher. Whether you’re managing a quarry or a small mining operation, neglecting routine care can lead to costly downtime, premature wear, and reduced output. If you are interested, you can learn more about best jaw crushers for small mines. This guide dives into actionable maintenance tips for jaw crushers, covering everything from daily inspections to component replacements. By following these strategies, you’ll minimize breakdowns and ensure your machine operates at peak efficiency.

Why Regular Maintenance for Jaw Crushers Matters

Jaw crushers endure extreme stress when crushing hard materials like granite or basalt. Without consistent upkeep, critical components like toggle plates, bearings, and jaw dies can fail unexpectedly. Implementing a proactive maintenance schedule not only prevents 20-30% of unplanned downtime but also aligns with cost-saving goals for operations prioritizing “low-cost jaw crusher maintenance” or “long-lasting crushing equipment.”

Daily Maintenance Checklist for Jaw Crushers

1. Inspect Lubrication Systems

Proper lubrication reduces friction in bearings and prevents overheating. Check oil levels daily and watch for contaminants. Use high-temperature grease for machines operating in harsh conditions, such as “jaw crushers in dusty mining environments.”

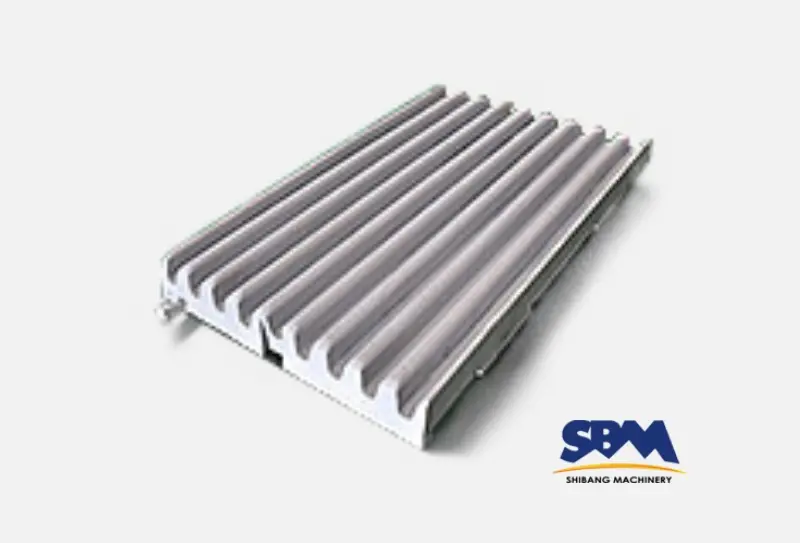

2. Monitor Jaw Plates and Dies

Worn or misaligned jaw plates reduce crushing efficiency and increase energy consumption. Look for uneven wear patterns or cracks, and rotate or replace plates when thickness decreases by 10-15%.

3. Tighten Bolts and Fasteners

Vibrations during operation can loosen bolts on the frame, toggle seats, and motor mounts. A daily torque check ensures structural integrity and prevents catastrophic failures.

Weekly and Monthly Maintenance Tasks

- Clean Dust and Debris: Accumulated material around the crusher frame or discharge area can obstruct airflow and cause overheating.

- Check Belt Tension: Loose belts slip and reduce power transmission efficiency. Adjust tension to manufacturer specifications.

- Test Safety Systems: Verify that emergency stop buttons and overload protection devices function properly.

Critical Long-Term Maintenance Strategies

Replace Worn-Out Components Proactively

Track the lifespan of high-wear parts like toggle plates (typically 6-12 months) and bearings (12-18 months). Scheduling replacements before failure aligns with best practices for “jaw crusher maintenance schedules”.

Calibrate Crusher Settings Seasonally

Adjust the CSS (closed side setting) based on material hardness and desired output size. For example, winter operations crushing brittle ore may require finer settings than summer tasks.

Upgrade to Durable Components

Invest in manganese steel jaw dies or ceramic-lined bearings if processing highly abrasive materials. These upgrades pay off in reduced downtime for operations focused on “high-efficiency jaw crusher maintenance.”

Common Mistakes to Avoid

- Ignoring Unusual Noises: Grinding or knocking sounds often indicate misaligned components or insufficient lubrication.

- Overloading the Crusher: Exceeding the recommended feed size strains the motor and accelerates wear.

- Using Incorrect Lubricants:Low-quality grease breaks down faster under high temperatures, increasing friction.

Tools for Streamlined Jaw Crusher Maintenance

Equip your team with:

- Laser alignment tools for precise jaw plate positioning.

- Infrared thermometers to monitor bearing temperatures.

- Vibration analysis software to detect imbalances early.

Conclusion: Maximize ROI Through Smart Maintenance

Adopting these jaw crusher maintenance tips can extend the life of your equipment by 30-50% while reducing repair costs. Whether you manage a single machine or a fleet of them, consistency is key. Beyond that, combine these practices with an operator training program focused on “safe jaw crusher operating techniques” to create a holistic maintenance culture. Finally, remember that a well-maintained crusher is not only reliable, but also a competitive advantage in a demanding industry.

Headquaters Office

Whatsapp:+8615225176731

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Website: https://www.mill-sbm.com/

Article Contents

Recent Posts

- Jaw Crusher for Limestone Processing: A Guide to EfficiencyAs limestone is widely used in construction and industry, its processing requires strong and durable jaw crusher to meet the needs of the industry. Among the many crushers, the jaw…

- Impact crusher with 300 TPH for large projectsWhen mining giants face mountains of iron ore or urban demolitions generate concrete avalanches, 300 TPH impact crusher emerges as material-processing titans. Beyond basic specs, we dissect how these industrial…

- Affordable Impact Crusher: A Game-Changer for Small Construction BusinessesSmall construction companies often face budget constraints, yet need reliable equipment – an affordable impact crusher. This crusher can bridge the gap, providing efficient material processing without a huge capital…