Email: [email protected]

Why Jaw Crushers Are the Unshakable Foundation of Mining?

In the rugged world of mining, where efficiency determines profitability, jaw crushers stand as the first line of defense against raw, unprocessed ore. From Australia’s iron-rich Pilbara region to Argentina’s lithium-rich salt flats, these machines shape the backbone of material extraction. But what makes them indispensable? Let’s dive into real-world operations and innovations that answer this question.

Jaw Crushers: Where Mining Productivity Begins

1. Turning Giants into Gravel: The Power of Primary Crushing

Picture a 5-ton chunk of iron ore hurtling toward a jaw crusher’s serrated plates. Within seconds, it’s reduced to fist-sized fragments—a daily reality at Rio Tinto’s Gudai-Darri mine in Australia. Here, jaw crushers process 2,000+ metric tons hourly, thanks to:

- Deep crushing chambers that eliminate material stagnation

- High inertia flywheels maintaining momentum even with irregular feed

- Hydraulic adjustment systems enabling on-the-fly size changes

Unlike gyratory crushers, jaw units thrive in operations requiring frequent relocation, like Canada’s Athabasca oil sands. Suncor Energy reports 22% faster setup times using modular jaw crushers versus traditional setups.

2. Material Versatility: From Marble to Mine Waste

In Italy’s Carrara basin, where Michelangelo once sourced marble, Fantini Group’s quarries use customized marble crushers with tungsten carbide jaws. This setup achieves two goals:

- Produces 0.5–2 cm fragments for luxury tile manufacturing

- Minimizes dust through integrated water spray systems

Meanwhile, in Sweden’s Kiruna iron mine, jaw crushers in mining handle -20°C temperatures and abrasive magnetite ore without performance loss—proving their adaptability.

Cost Efficiency That Resonates Across Continents

Case Study: Copper Mining’s Secret Weapon in Chile

At Codelco’s Radomiro Tomic mine, jaw crushers in mining cut costs three ways:

- Energy savings: 18% lower kWh/ton vs. impact crushers (2022 internal audit)

- Component longevity: Manganese liners last 6–8 weeks in high-silica ore

- Recycling synergy: Crushed waste rock repurposed for road base

“Our jaw crushers are the unsung heroes,” says plant manager Luis Torres. “They handle 90% of our primary crushing needs with <3% downtime.”

The Aggregate Revolution: From Demolition to Highways

U.S. Midwest Crushing & Screening repurposes Chicago’s demolished buildings using jaw crushers. The result?

- 500 tons/day of recycled concrete aggregate

- 40% cost reduction vs. materials for I-80 highway projects

- LEED certification points for eco-conscious developers

Engineering Breakthroughs Redefining Reliability

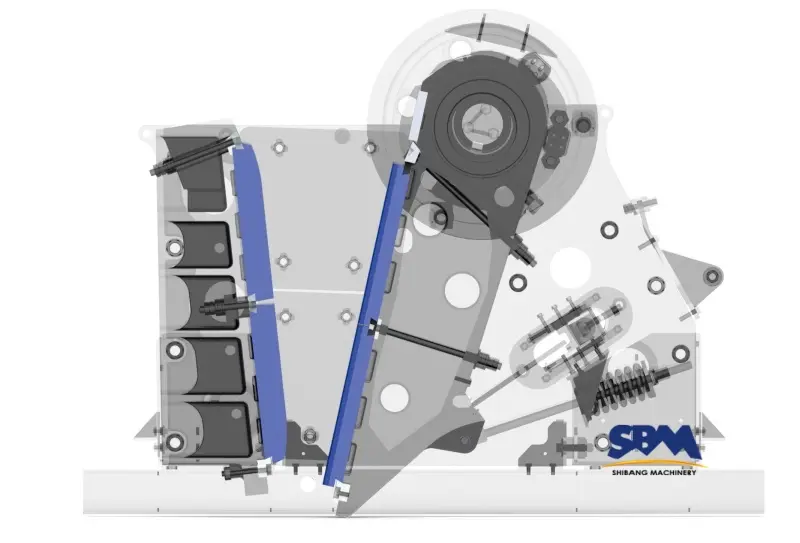

SBM Crusher Solutions: Where Durability Meets Innovation

SBM’s C6X series, used in South Africa’s Bushveld platinum belt, features:

- International Top Configurations: High-quality raw materials and reliable design can provide sufficient equipment strength and remarkable durability of C6X Jaw Crusher during super-hard material crushing and thus reduce the maintenance costs.

- High-quality Casting Ensures Reliable Performances: C6X Jaw Crusher is equipped with such core rotating components as high-quality casting movable jaw body, large-eccentric heavy-duty forged eccentric shaft, cast flywheel with a high moment of inertia and high-strength integrated cast steel bearing box, as well as strong power with reasonable speed configurations.

- Digitalized Processing, Higher Precision: There are tens of lines of numerical controlling machine tools. Operations such as steel plates’ cutting, bending, planing, milling and paint spraying are all controlled numerically. The machining precision is high, especially for the core parts.

The Road Ahead: Sustainable Crushing Takes Center Stage

Lithium’s New Frontier: Argentina’s Green Crusher Initiative

In the “Lithium Triangle,” Livent Corp’s Fenix project uses SBM jaw crushers powered entirely by solar farms. Early data shows:

- 0 fossil fuels used in primary crushing

- 2.8-ton CO₂ reduction per 100 tons processed

- AI-driven feed optimization boosting yield by 14%

Urban Mining’s Quiet Revolution

Amsterdam’s Circular Construction Hub proves jaw crushers in mining aren’t just for remote mines:

- Noise-dampened jaw crusher units operate in residential areas

- Process 80 tons/hour of demolition concrete

- Integrated metal detectors prevent rebar jams

Explore More:

- How jaw crushers achieve 24/7 reliability in extreme conditions

- The evolving role of jaw crusher in rock crusher ecosystems

- Case study: Crushers in aggregate production fuel NYC’s Hudson Yards development

- Why Italian marble producers trust specialized marble crusher tech

- Performance benchmarks: SBM crusher vs traditional models in gold mining

From the Australian Outback to Europe’s eco-conscious cities, jaw crushers continue rewriting the rules of mineral processing. Their blend of brute force and technological finesse ensures they’ll remain mining’s cornerstone—no matter what the future digs up.

Headquaters Office

Whatsapp:+8615225176731

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Website: https://www.mill-sbm.com/

Article Contents

Recent Posts

- How Jaw Crusher Design Enhances Operational Efficiency in Mining and ConstructionThe efficiency of a jaw crusher depends on its design. These design principles maximize production while minimizing energy consumption and downtime. Below, we analyze which key design features contribute to…

- Why Jaw Crushers Are the Unshakable Foundation of Mining?In the rugged world of mining, where efficiency determines profitability, jaw crushers stand as the first line of defense against raw, unprocessed ore. From Australia’s iron-rich Pilbara region to Argentina’s…

- What Industries Primarily Use Jaw Crushers? A Global PerspectiveThe applications of jaw crushers are very wide and numerous industries mainly use them. While jaw crushers might seem like simple mechanical workhorses, their impact on modern industry is anything…