Correo electrónico: [email protected]

Guía de selección de placas de mandíbula: Optimizar el rendimiento para su operación de trituración

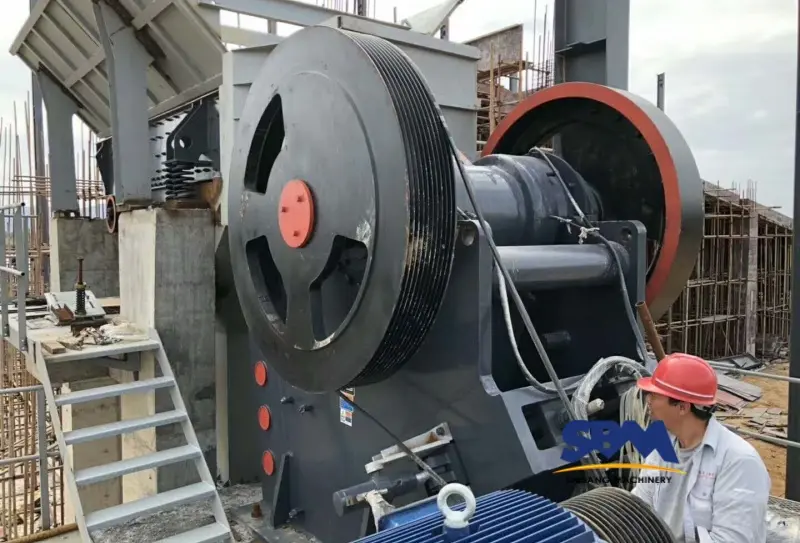

Choosing the right jaw plates can increase youreficiencia de trituracion por 25-40% mientras reduce los costos de reemplazo. This comprehensivejaw plate selection guide explains how material composition, Diseño de perfil de dientes, y las condiciones de funcionamiento determinan la longevidad de la placa. Ya sea que esté operando una trituradora C6X o modelos más antiguos, these insights will help you make informed decisions.

Key Factors in Jaw Plate Selection

Material Composition Choices

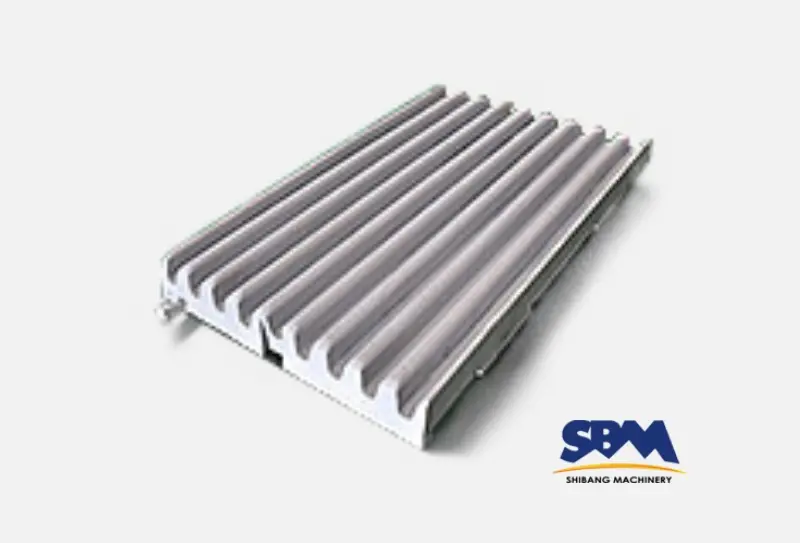

Modern jaw plates use three primary materials:

- Manganese Steel (14-18%): Ideal for general-purposequarry applications, withstands 50-70k tons before replacement

- Chrome Iron Alloy: 30% longer lifespan in abrasive materials like granite

- Ceramic-Enhanced: Reduces wear by 45% in high-silica content operations

Tooth Profile Design Considerations

The plate’s tooth configuration directly impacts yourcrusher’s working mechanism:

| Profile Type | Best For | Output Size Range |

|---|---|---|

| Straight | Primary crushing | 150-300 milímetro |

| Waved | Secondary reduction | 50-120 milímetro |

| Hybrid | Mixed material feeds | 30-150 milímetro |

4-Step Selection Process

- Analyze Feed Material: Test hardness (escala de Mohs) and abrasiveness

- Determine Crusher Type: C6X Series Jaw Crusher requires specific plate locking systems

- Calculate Economic Lifespan: Balance initial cost vs tons crushed/$

- Verify Compatibility: Check mounting system dimensions (±2mm tolerance)

Maintenance Synergy: Plates and Crusher Health

Properjaw crusher maintenance extends plate lifespan by 60%:

- Rotate plates every 200-300 horas de funcionamiento

- Maintain correct CSS settings (affects wear patterns)

- Use laser alignment tools for precise installation

Estudio de caso: Granite Quarry Optimization

A Brazilian operation achieved 32% cost reduction by:

- Switching from standard Mn14 to Mn18Cr2 plates

- Implementing bi-weekly wear measurements

- Syncing replacements with scheduled maintenance downtime

Advanced Monitoring Techniques

- 3D wear scanning for precise remaining thickness analysis

- AI-powered wear rate prediction models

- Ultrasonic hardness testing for material verification

Common Selection Mistakes

- Choosing cheap plates needing 3x more frequent replacement

- Ignoring material compatibility (P.EJ., zinc contamination)

- Overlooking plate weight impacts on crusher kinematics

Strategic Selection Pays Dividends

Masteringselección de placas de mandíbula requires understanding your material, machine type (like C6X models), and operational goals. Pair this guide with regular preventive maintenance to achieve 18-24 month plate lifespans even in demanding conditions. Remember: The optimal plate today may differ tomorrow – re-evaluate selections with major material changes.

Oficina central

Whatsapp:+8615225176731

Correo electrónico: [email protected]

DIRECCIÓN: No. 1688, Camino del este de Gaoke, Nuevo distrito de Pudong, Llevar a la fuerza, Porcelana.

Sitio web: https://www.mill-sbm.com/

Contenido del artículo

Mensajes recientes

- Why Jaw Crushers Are the Unshakable Foundation of Mining?In the rugged world of mining, where efficiency determines profitability, jaw crushers stand as the first line of defense against raw, unprocessed ore. From Australia’s iron-rich Pilbara region to Argentina’s…

- Lo que las industrias usan principalmente trituradoras de mandíbula? Una perspectiva globalLas aplicaciones de las trituradoras de la mandíbula son muy amplias y numerosas industrias las usan principalmente. Mientras que las trituradoras de la mandíbula pueden parecer simples caballos de batalla mecánicos, Su impacto en la industria moderna es cualquier cosa ...

- Comprender los componentes clave de las trituradoras de impacto para una eficiencia de trituración óptimaEsta guía explora los componentes clave de las trituradoras de impacto, sus funciones, y aplicaciones del mundo real en industrias globales. Componentes clave de las trituradoras de impacto 1. Ensamblaje del rotor: El corazón de la eficiencia aplastante ...