Correo electrónico: [email protected]

Guía paso a paso para reemplazar los revestimientos de la cárcel: 8 Fases clave

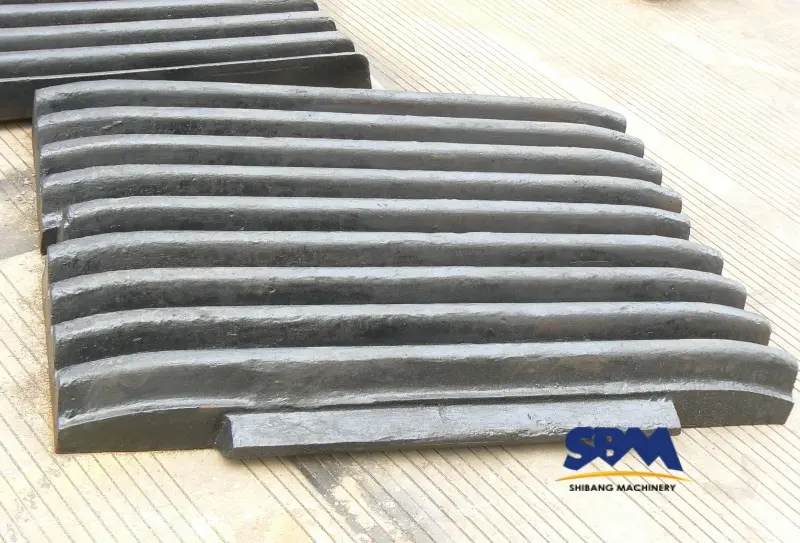

Properly replacing jaw crusher liner increases production efficiency by 40% y extiende la vida de los componentes de 2-3 años. This comprehensive guide details professional techniques used insmall and large mining operations, cubriendo protocolos de seguridad, Requisitos de herramienta, y métodos de alineación de precisión. Follow our 8-phase process to minimize downtime to under 4 hours per replacement.

Pre-Replacement Preparation

1. Safety Lockout Procedure

- Disconnect power supply and engage mechanical lockout

- Release hydraulic pressure (>5 minutes bleed time)

- Install fall protection for crusher pit access

2. Tool & Material Checklist

| Tool | Specification |

|---|---|

| Hydraulic Jack | 50-ton capacity |

| Torque Wrench | 300-800 N·m range |

| Liner Lifting Clamp | SWL 2,000kg |

Liner Replacement Process

3. Remove Worn Liners

- Loosen wedge bolts in diagonal pattern (30% torque reduction)

- Usarliner removal tools to break corrosion bond

- Extract upper wedges first, then side plates

4. Clean & Inspect Mounting Surface

- Remove debris with pneumatic chisel

- Check for cracks using dye penetrant

- Verify flatness (<0.5mm/m tolerance)

5. Install New Liners

| Component | Torque Spec | Sequence |

|---|---|---|

| Fixed Jaw | 650 N·m | Center-out |

| Movable Jaw | 720 N·m | Cross pattern |

6. Alignment Verification

Use laser alignment tools to ensure:

- Parallelism <0.2mm/m

- Vertical runout <0.3mm

- Propercrushing chamber geometry

Post-Installation Procedures

7. Run-in Process

- Start with 50% feed rate for 2 horas

- Monitor vibration (<4.5 mm/s RMS)

- Retorque after 8 hours operation

8. Documentación & Analysis

- Record liner serial numbers

- Measure initial wear pattern

- Updatepredictive maintenance schedule

Common Mistakes & Solutions

| Error | Consequence | Prevention |

|---|---|---|

| Improper torque | Liner movement | Use calibrated wrench |

| Missed alignment | Premature wear | Laser verification |

Quarry Productivity Improvement

A limestone operation reduced liner replacement time from 6.5 a 3.8 hours by:

- Implementing our 8-step process

- Using optimized liner profiles

- Training crew on crusher kinematics

Essential Tools for Efficient Replacement

- Liner handler with vacuum lift

- Infrared thermal camera (check bearing temps)

- Digital thickness gauge (wear measurement)

Precision Saves Costs

Replacing jaw crusher liner requires understanding torque specifications, alignment tolerances, and proper run-in procedures. Por lo tanto, by integrating this guide with your preventive maintenance program andequipment documentation, operations typically achieve 18-24 month liner lifecycles even in abrasive conditions.

Oficina central

Whatsapp:+8615225176731

Correo electrónico: [email protected]

DIRECCIÓN: No. 1688, Camino del este de Gaoke, Nuevo distrito de Pudong, Llevar a la fuerza, Porcelana.

Sitio web: https://www.mill-sbm.com/

Contenido del artículo

Mensajes recientes

- Jaw Crusher para procesamiento de piedra caliza: Una guía de eficienciaAs limestone is widely used in construction and industry, its processing requires strong and durable jaw crusher to meet the needs of the industry. Among the many crushers, the jaw…

- Impacto trituradora con 300 TPH para grandes proyectosCuando los gigantes mineros enfrentan montañas de mineral de hierro o demoliciones urbanas generan avalanchas de concreto, 300 TPH Impact Trither emerge como titanes de procesamiento de material. Más allá de las especificaciones básicas, Diseccionamos cómo estos industriales ...

- Trituradora de impacto asequible: Un cambio de juego para pequeñas empresas de construcciónLas pequeñas empresas de construcción a menudo enfrentan limitaciones presupuestarias, Sin embargo, necesita un equipo confiable – una trituradora de impacto asequible. Esta trituradora puede cerrar la brecha, Proporcionar procesamiento de material eficiente sin un gran capital ...