Correo electrónico: sales@mill-sbm.com

¿Cuál es la eficiencia de trituración de una trituradora de piedra??

Crushing efficiency of stone crusher is the ratio of stone crusher’s operation to the fed material size to give the required size. It usually varies, but the crushing efficiency is related to the crushing ratio of the stone crusher. Hence, increasing the crushing efficiency of stone crusher reduction ratio depends on the amount of material fed into the crusher’s chamber.

How to calculate the crushing efficiency of stone crusher?

The method for crushing efficiency is:

Crushing efficiency = (Actual amount of material smaller than the specified size / Theoretical amount of material smaller than the specified size) x 100%

How to improve the crushing efficiency of my stone crusher?

There are many factors that affect crushing efficiency. These factors include but are not limited to:

Characteristics of crushing stone

- Size and shape of stone: Larger and irregularly shaped stones require more crushing energy. Por lo tanto, the crushing efficiency will be reduced.

- Hardness and abrasiveness of the crushed material: Harder and more abrasive materials will reduce crushing efficiency. For the same crusher, concrete crushing y limestone crushing have different crushing efficiencies.

Types of stone crushers

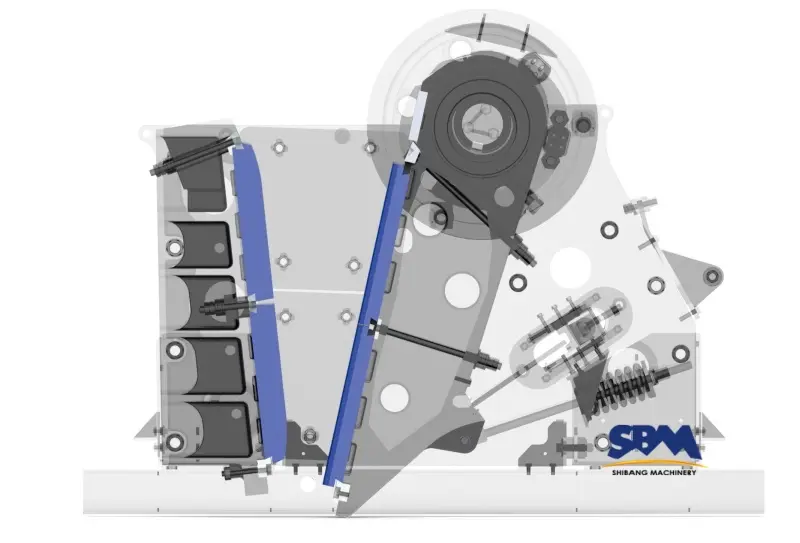

- Crushing mechanism: Different types of crushers (trituradoras de mandíbula, trituradoras de impacto, trituradoras de cono, etc.) have different crushing mechanisms. Therefore they have different efficiencies.

- Characteristics of stone crushers: Factors such as crusher speed, stroke, crushing chamber geometry and crusher settings all affect crushing efficiency.

Operating conditions of stone crusher

- Feeding rate: Excessive feeding will cause the stone crusher to be overloaded or even jammed. This will reduce the crushing efficiency, thereby affecting the production process.

- Crusher speed: Higher crusher speed can improve the efficiency of certain types of crushers, but too high a speed will increase the wear of the crusher and will also increase production costs accordingly.

Maintenance and wearing parts

Regular maintenance and timely replacement of wearing parts can ensure that the stone crusher operates at optimal crushing efficiency. As the saying goes: If a worker wants to do his job well, he must first sharpen his tools.

Moisture content of crushed materials

The higher the contenido de humedad of the crushed materials, the greater the adhesion between the materials will be. Por lo tanto, wet materials will reduce the crushing efficiency of the stone crusher.

Particle size distribution of materials

Uniform material particle size distribution can improve crushing efficiency.

Circular crushing production line

When the stone crusher operates in a circulating crushing production line with a vibrating screen, the vibrating screen can recycle larger particles into the crusher for further crushing. This will improve the crushing efficiency.

Oficina central

Whatsapp:+8615225176731

Correo electrónico: sales@mill-sbm.com

DIRECCIÓN: No. 1688, Camino del este de Gaoke, Nuevo distrito de Pudong, Llevar a la fuerza, Porcelana.

Sitio web: https://www.mill-sbm.com/

Contenido del artículo

Mensajes recientes

- Más allá de las rocas: Los sorprendentes materiales pueden procesar las trituradoras de la mandíbulaMientras “trituradora de rocas” podría conjurar imágenes de montañas de granito, New Jaw Crushers Process Materials que sorprenderían incluso a los ingenieros experimentados. Examinemos sus verdaderas capacidades a través de datos operativos globales y ...

- Cómo el diseño de la trituradora de la mandíbula mejora la eficiencia operativa en la minería y la construcciónLa eficiencia de una trituradora de la mandíbula depende de su diseño. Estos principios de diseño maximizan la producción mientras minimizan el consumo de energía y el tiempo de inactividad.. Abajo, Analizamos a qué características de diseño clave contribuyen ...

- Por qué las trituradoras de la mandíbula son la base inquebrantable de la minería?En el rugoso mundo de la minería, donde la eficiencia determina la rentabilidad, Jaw Crushers se encuentra como la primera línea de defensa contra Raw, mineral sin procesar. Desde la región de Pilbara rica en hierro de Australia hasta la de Argentina ...