پست الکترونیک: [email protected]

Fixed Jaw Crusher vs Gyratory Crusher: What’s the Best Choice for Your Project?

When selecting primary crushing equipment, the debate betweenfixed jaw crusher در مقابلgyratory crusher often arises. Both machines excel in reducing large rocks but differ significantly in design, efficiency, and application. This guide breaks down their differences, real-world use cases, and how to choose the right crusher for projects likeconcrete recycling or mining.

Core Design Differences: How They Work

Fixed Jaw Crusher Structure

بوهاfixed jaw crusher operates using compressive force. Its two vertical jaws—one stationary (fixed) and one movable—crush materials by pressing them until they break. Models like thePE 600 × 9000000000000000 are popular for their simplicity and reliability in quarries.

Gyratory Crusher Mechanics

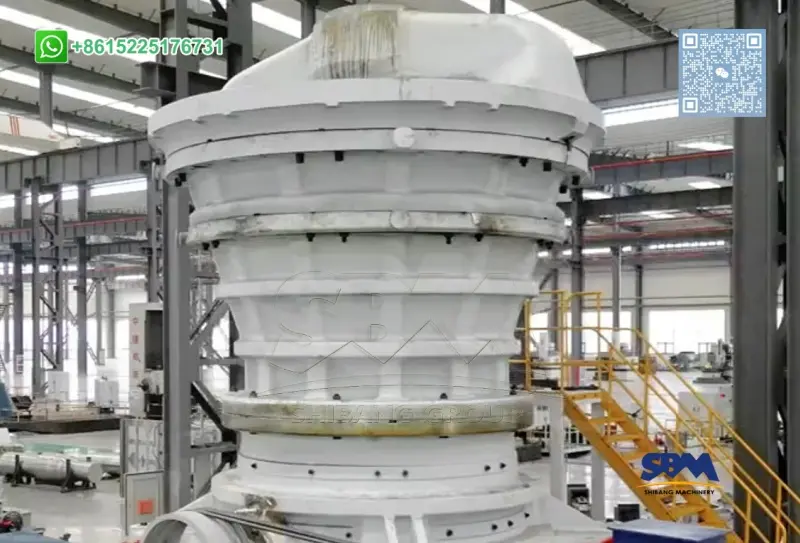

سنگ شکن use a rotating mantle and concave surfaces. The central spindle gyrates, creating a compressive action that crushes materials. These machines are taller and bulkier, making them ideal for high-capacity mining operations.

Performance Comparison: Efficiency & Output

Crushing Capacity

- Fixed jaw crushers: Best for medium-scale projects likeconcrete recycling or aggregate production. They handle abrasive materials well but require frequent maintenance.

- سنگ شکن: Higher throughput (up to 14,000 t/h) suits large mining operations. Their continuous crushing cycle reduces downtime.

Energy Consumption

Gyratory crushers consume 15–20% less energy per ton in high-capacity settings. با این حال, smaller operations may preferfixed jaw crushers like theخردکن فک موبایل در مقابل شکن فک ثابت for lower upfront costs.

Maintenance & Operational Costs

Wear Parts Replacement

- Fixed jaw crushers: Cheaper to maintain. Replaceable parts like toggle plates and liners are accessible.

- سنگ شکن: Complex assembly increases downtime during mantle or concave replacements.

Longevity

Gyratory crushers last longer under heavy-duty conditions, whileسنگ شکن های فکی like thePE 600×900 offer cost-effective solutions for shorter projects.

مطالعات موردی جهانی: Where Each Crusher Shines

مورد 1: Concrete Recycling in Germany

A Berlin-based recycling plant opted for afixed jaw crusher to process demolition waste. Its compact design and easy integration with screening systems streamlined theirconcrete recycling workflow.

مورد 2: Copper Mining in Chile

A Chilean mine uses a gyratory crusher to process 12,000 tons of ore daily. همزمان, the machine’s high capacity and low energy use reduced operational costs by 22%.

How to Choose Between Them

Consider these factors:

- Project Scale: Small to medium? Pick afixed jaw crusher. Large mining? Opt for gyratory.

- Material Hardness: Abrasive aggregates? Jaw crushers perform better.

- Budget: Gyratory crushers have higher upfront costs but lower long-term expenses.

For mobile setups, exploreخردکن فک موبایل در مقابل شکن فک ثابت comparisons.

Final Thoughts

Bothfixed jaw crusher در مقابلgyratory crusher have unique strengths. While jaw crushers dominateconcrete recycling and mid-sized quarries, gyratory models excel in high-volume mining. Assess your project’s needs, material type, and budget to make an informed choice.

Need a reliable crusher? Learn more about our PE 600 × 9000000000000000 or explore our guide to gyratory crushers for industrial applications.

دفتر مرکزی

واتساپ:+8615225176731

پست الکترونیک: [email protected]

نشانی: خیر. 1688, جاده شرقی گائوک, ناحیه جدید پودونگ, شانگهای, چین.

سایت اینترنتی: https://www.mill-sbm.com/

محتویات مقاله

پستهای اخیر

- سنگ شکن فک برای پردازش سنگ آهک: راهنمای کارآییاز آنجا که سنگ آهک به طور گسترده ای در ساخت و ساز و صنعت استفاده می شود, پردازش آن برای رفع نیازهای صنعت نیاز به سنگ شکن فک قوی و بادوام دارد. در میان بسیاری از سنگ شکن ها, فک ...

- سنگ شکن ضربه با 300 TPH برای پروژه های بزرگهنگام استخراج غول ها با کوههای سنگ آهن یا تخریب شهری بهمن های بتونی تولید می کنند, 300 سنگ شکن ضربه TPH به عنوان تایتان های پردازش مواد ظاهر می شود. فراتر از مشخصات اساسی, ما چگونگی این صنعتی را مشخص می کنیم ...

- سنگ شکن مقرون به صرفه: یک تغییر دهنده بازی برای مشاغل ساختمانی کوچکشرکت های کوچک ساختمانی اغلب با محدودیت های بودجه روبرو هستند, با این حال به تجهیزات قابل اعتماد نیاز دارید – یک سنگ شکن مقرون به صرفه. این سنگ شکن می تواند شکاف را پر کند, ارائه پردازش مواد کارآمد بدون سرمایه عظیم ...