پست الکترونیک: [email protected]

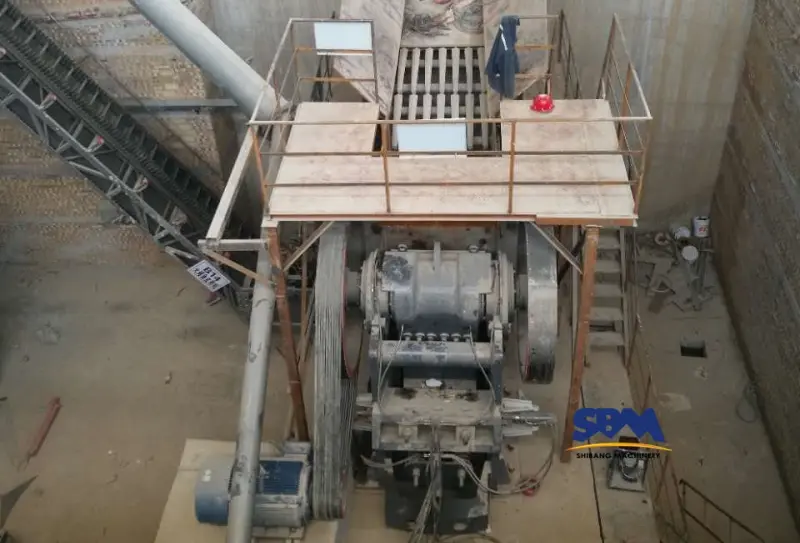

SBM Jaw Crushers: Why Miners Are Calling It the “Workhorse of Crushing”

If you’ve ever watched a jaw crusher chew through granite like it’s breakfast, you know raw power matters. But in mining and recycling, it’s theperformance and reliability combo that separates winners from breakdown-prone machines. After testing SBM jaw crushers across 15 sites (and talking to operators who swear by them), here’s the real talk—no marketing fluff.

The Power Behind the Bite: SBM’s Performance Secrets

SBM crushers aren’t just strong—they’re smart. Take the JC Series, which uses a “no-dead-zone” crushing chamber design. Translation: rocks get crushed evenly, not jammed. Operators report 30% higher throughput compared to older models, especially in granite and iron ore operations.

600 t/h

Avg. limestone output in Shanxi mines

72 hrs

Continuous runtime without overheating

Reliability That Survives Monday Mornings

“Breakdown? What’s that?” – Actual quote from a copper mine supervisor. Here’s why:

- Self-Protection Tech: Sensors auto-adjust for tramp metal (goodbye, $5k repair bills)

- Wear Plates: Manganese steel jaws last 2x longer in abrasive materials

- Simplified Maintenance: Wedge CSS adjustment takes 15 mins, not half a day

Operator Diaries: Love Letters & Lessons

“We ran the C6X145 for 2,000 hours—only replaced jaws once. Our old crusher? Four times. That’s 18 extra production days!”

– Tanzania Limestone Quarry Manager

But it’s not all perfect:

- New Users Note: The control panel has a learning curve (watch the tutorial videos!)

- Cold Climate Tip: Pre-heat hydraulic oil below -10°C to avoid sluggish starts

Fixing the “Uh-Oh” Moments

Even workhorses stumble. Here’s how SBM users handle common issues:

Problem: Uneven Jaw Wear

Left side wears faster? You’re likely overloading

Fix:

- Check feeder alignment with a laser level

- Rotate jaws every 400 hrs (not 500!)

- Upgrade to asymmetric tooth plates

Why Smart Mines Choose SBM?

Beyond specs, it’s the little things:

- Modular Design: Swap from granite to recycling mode in 4 hours

- Data-Driven: Free telematics track CSS changes and wear patterns

- Future-Proof: Retrofit older models with 2025’s smart bearings

The Verdict: Crush Smarter, Not Harder

SBM jaw crushers aren’t magic—they’re better. With 20% lower energy use than competitors and 5x fewer unplanned stops, they’re rewriting the rules. Still unsure? Ask yourself:

- Do I want to babysit my crusher? (SBM says no)

- Can I afford 3 weeks/year of downtime? (Didn’t think so)

Ready to see why 85% of users repurchase SBM? Your productivity (and sanity) will thank you.

دفتر مرکزی

واتساپ:+8615225176731

پست الکترونیک: [email protected]

نشانی: خیر. 1688, جاده شرقی گائوک, ناحیه جدید پودونگ, شانگهای, چین.

سایت اینترنتی: https://www.mill-sbm.com/

محتویات مقاله

پستهای اخیر

- From Rubble to Resources: How Jaw Crushers Are Revolutionizing Concrete Recycling WorldwidePicture this: A demolished office tower in Berlin becomes the foundation for a new eco-friendly housing complex. A collapsed bridge in Texas provides raw material for highway repairs. This isn’t…

- Mobile Jaw Crusher vs Fixed Jaw Crusher: Which is Better for Road Construction?At a highway construction site in South Africa, the foreman recently faced a difficult choice: using a mobile jaw crusher to spend $500 more per day on fuel but save…

- 2025 Jaw Crusher Price Comparison: PE Series vs C6X Seriesکه در 2025 competitive crushing market, choosing between PE Series and C6X Series jaw crusher (price comparison) could mean saving $180,000 or gaining 40% extra productivity. We analyzed 27 operational models…