پست الکترونیک: [email protected]

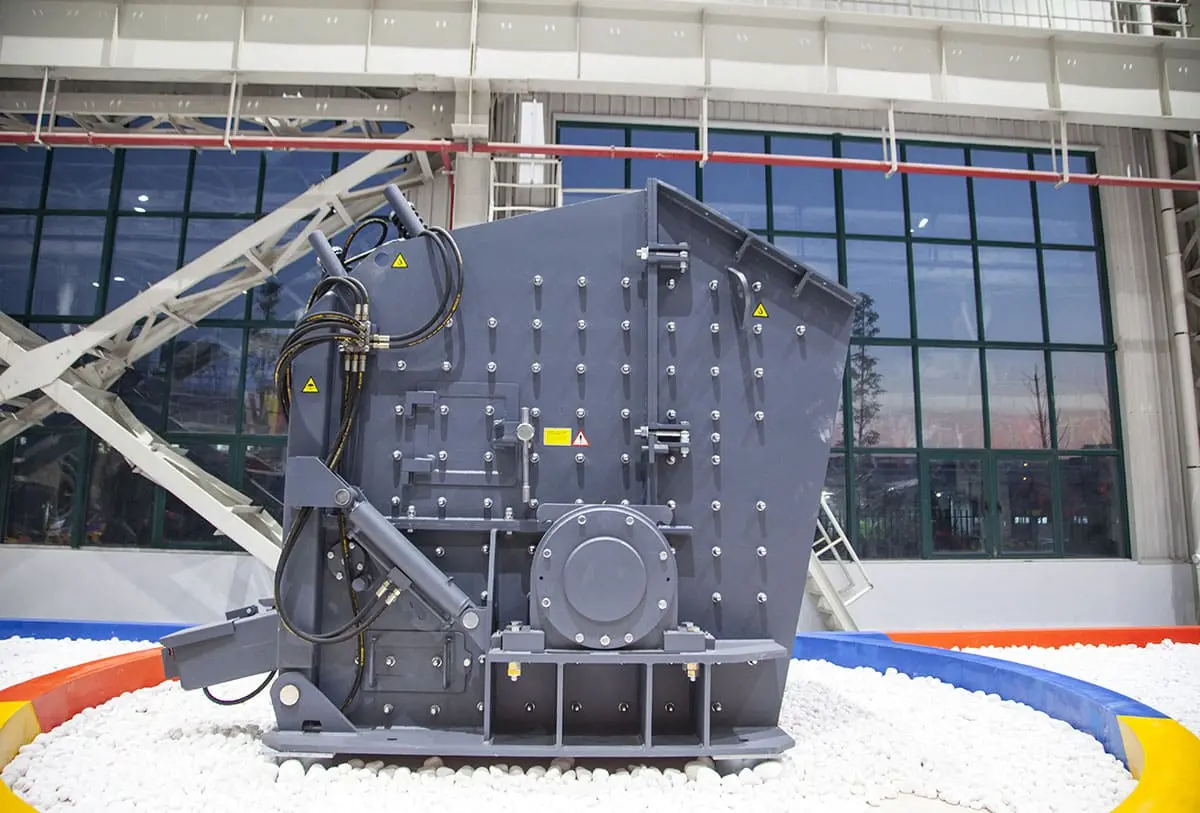

سنگ شکن ضربه ای PFW

سنگ شکن ضربه ای PFW (Also known as “European Impact Crusher”) is mainly used in metallurgy, mine, سیمان, chemical engineering, fire resistant materials, ceramics and other industries, as well as in the expressway construction, water conservancy projects, aggregate and machine-made sand fields, و غیره.

ویژگی های محصول: The use of automated hydraulic jacking device makes checks and maintenance easier and reduces labor costs.

- اندازه ورودی: 0-700میلی متر

- ظرفیت: 70-400TPH

- مواد: سنگ آهک, فلدسپات, کلسیت, تالک, باریت, دولومیت, kaolin, گچ, graphite, و غیره.

Top Technology, Unique Design

PFW Impact Crusher adopts world-class production technologies. It is made up of high-end materials. The design of heavy-duty rotor and strict checks allow the rotor to have high quality. در ضمن, the unique fixed device makes the hammer more reliable.

Cast Steel Structure, High Holding Capacity

PFW Impact Crusher’s bearing seat uses integral cast steel structure, which ensures stable operation. Larger bearings boast higher holding capacity.

Semi-automatic Operation Makes Maintenance Easy and Convenient

PFW Impact Crusher can equip the hydraulic control system. By the hydraulic device, the size of discharge opening and the discharging granularity can get controlled quickly. در کنار, the automatic hydraulic jacking device is helpful for quick replacement of vulnerable parts like the hammer so that the downtime for maintenance can be shortened indirectly.

Simplified Technological Process, Wide Applications

The two-cavity crushing of PFW Impact Crusher can simplify the technological process of coarse and medium-coarse crushing while the three-cavity crushing makes PFW Impact Crusher perform exceptionally well in fine and superfine crushing. Two kinds of crushing cavities can meet the vast majority of coarse, medium and fine crushing operations.

پردازش دیجیتالی شده, دقت بالاتر

ده ها خط ماشین ابزار کنترل عددی وجود دارد. عملیاتی مانند صفحات فولادی’ برش دادن, خم شدن, برنامه ریزی, فرز و پاشش رنگ همگی به صورت عددی کنترل می شوند. دقت ماشینکاری بالاست, مخصوصا برای قطعات اصلی.

عرضه کافی قطعات یدکی, عمل بدون نگرانی

SBM, که تجارت آن تولید و فروش را پوشش می دهد, مسئولیت هر ماشینی که توسط خودمان تولید می شود را بر عهده می گیرد. ما می توانیم به مشتریان خدمات فنی در مورد محصولات و قطعات یدکی اصلی ارائه دهیم تا از عملکرد بدون نگرانی اطمینان حاصل کنیم.

اصل کار

PFW Impact Crusher breaks materials with impact force. When materials enter the working area of hammer, they may be crushed under the high-speed shock and then thrown onto the impact device above the rotor for another crushing. بعد, materials bounce from the lining plate to the working area of hammer again. This process repeats continuously until materials reach qualified granularity and are discharged. Adjusting the gap between the impact rack and the rotor rack can change the granularity and shape of finished products. Behind the impact plate is a spring safety device. When unbreakable materials enter the crushing chamber, the impact rack goes backwards to discharge unbreakable materials out of the crusher.

پارامترهای محصول

| مدل | Rotor spec (میلی متر) | باز شدن خوراک (میلی متر) | حداکثر اندازه تغذیه (میلی متر) | ظرفیت(t/h) | قدرت(کیلووات) | ابعاد کلی (میلی متر) |

| PFW1214Ⅲ | Ф1150×1400 | 570×1430 | 250 | 90-170 | 132 | 2550×2310×2100 |

| PFW1315Ⅲ | Ф1300×1500 | 625×1530 | 300 | 180-270 | 200 | 2960×2570×2380 |

| PFW1415Ⅲ | Ф1400×1500 | 800×1530 | 350 | 280-350 | 250-315 | 3120×2650×2660 |

توجه داشته باشید:

تصاویر محصول و پارامترهای مربوط به مدل ها, داده ها, اجراها و مشخصات موجود در این وب سایت فقط برای مرجع است. این احتمال وجود دارد که SBM ممکن است تغییراتی در اطلاعات ذکر شده در بالا ایجاد کند. برای پیام های خاص, لطفاً به کتابچه راهنمای کاربر و اشیاء واقعی مراجعه کنید. بدون دستورالعمل خاص, SBM این حق را برای خود محفوظ می دارد که تمام داده های مربوط به این وب سایت را توضیح دهد.