E-mail: [email protected]

Traitement de la calcite

SBM provides calcite mining equipment such as concasseurs à mâchoires, concasseurs à percussion, concasseurs à cône, and so on. You may also make use of our auxiliary equipment, such as ball mills and vertical roller mills.

Introduction

Calcite is a mineral that is commonly found in sedimentary rocks, such as limestone and marble. It is also present in the shells of marine organisms and in the skeletons of some animals. Calcite plays an important role in a variety of industries, including construction, agriculture and pharmaceuticals. In order to utilize calcite, we must first treat it to remove impurities and prepare it for its intended use. Calcite processing involves several steps, y compris le broyage, affûtage, and sorting. This process is essential for producing high-quality calcite products that meet the needs of various industries.

One of the most significant minerals is calcite. Colorless, white, pink, yellow, and brown, with a Mohs hardness of 3 and a density of 2.71 g/cm3.

Crusher For Calcite

The calcite crusher manufactured by SBM has many uses in mining, métallurgie, matériaux de construction, road and rail transportation, water conservancy, chemical industry and other industries. It has a high crushing ratio, even if the finished product is monodisperse, a simple structure, dependable operation, entretien facile, minimal maintenance, and economic performance.

Calcite Crusher has simple design, stable performance, low failure rate, low maintenance needs, hors de porté, high efficiency and good quality. Calcite crusher plays a very important role in mining, métallurgie, industrie chimique, construction, ciment, sand and gravel and other industries. They also have double insurance and control over the hydraulic and lubricating systems.

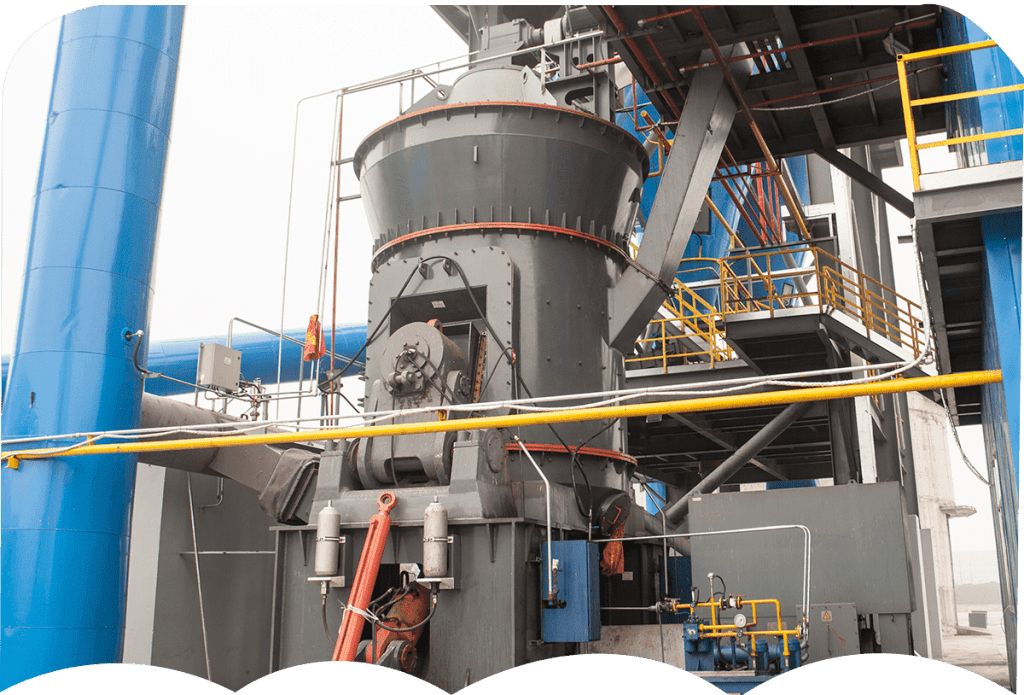

Calcite Mill

The calcite ball mill is the primary grinding instrument in the manufacturing plant. Calcite ball mills have several uses in the building materials, chemicals, and mineral processing industries, as well as for grinding a wide range of ores and other materials. En outre, according to the different loads used in the mine, there are two types of ball mills: screen type and overflow type. Dry process and wet process are two of these categories.

Please contact our online expert if you want to learn more about the cost and availability of calcite mills or crushers!

For calcite crushing, SBM provides jaw crushers, concasseurs à percussion, concasseurs à cône, and other mining calcite crushing equipment. If your final particle size need is greater, you may also use our calcite-related equipment, such as ball mills and vertical roller mills. As China’s largest maker of mining and construction equipment, we offer the best after-sales service and a lot of successful manufacturing skills. Our tools will also give you with considerable advantages for calcite production process.

The Benefits of Calcite Processing for Industrial Applications

Calcite is a mineral that is widely used in various industrial applications. It is a versatile mineral that can be processed into different forms, such as powder, granules, and crystals. Calcite processing involves various techniques that are used to extract and refine the mineral for use in different industries. The benefits of calcite processing for industrial applications are numerous, and this article will explore some of them.

Improve the purity of minerals

One of the primary benefits of calcite processing is that it enhances the purity of the mineral. Calcite frequently occurs naturally mixed with other minerals, which may diminish its quality and value. Processing calcite involves separating it from other minerals and refining it to increase its purity. This makes it more valuable and suitable for use in various industrial applications.

Improve the physical properties of minerals

Calcite processing also improves the physical properties of the mineral. The processing techniques used can alter the size, forme, and texture of the calcite crystals, making them more suitable for specific applications. Par exemple, calcite crystals can be ground into a fine powder, which is ideal for use in paints, revêtements, and plastics. Alternativement, larger calcite crystals can be used in construction materials, such as concrete and asphalt.

Improve the chemical properties of minerals

Another benefit of calcite processing is that it can improve the chemical properties of the mineral. Calcite is a calcium carbonate mineral, and its chemical composition can be altered through processing. This can make it more suitable for use in different industries. Par exemple, we can treat calcite with acid to produce calcium chloride. The role of calcium chloride is to produce deicing agents and food additives.

Increase the economic value of minerals

Calcite processing can also enhance the economic value of the mineral. The processing techniques used can increase the yield of the mineral, making it more profitable for mining companies. En outre, we can sell refined calcite at a higher price than raw ore, thereby increasing the revenue generated from its mining.

Other important benefits

The use of calcite in various industrial applications is widespread. It is used in the production of cement, verre, céramique, and paper. It is also used as a filler in plastics, paints, and coatings. Calcite is used in the production of lime, which is used in agriculture, water treatment, and construction. The versatility of calcite makes it a valuable mineral for many industries.

En conclusion, calcite processing offers numerous benefits for industrial applications. It enhances the purity, physical, and chemical properties of the mineral, making it more suitable for use in different industries. Calcite processing can also increase the economic value of the mineral, making it more profitable for mining companies. The versatility of calcite makes it a valuable mineral for many industries, and its importance is likely to continue to grow in the future.

Conclusion

Calcite processing involves various steps such as crushing, affûtage, and classification. The process is used to produce high-quality calcite powder that is used in various industries such as construction, agriculture, and pharmaceuticals. The process also involves the removal of impurities to ensure that the final product is of high purity. Calcite processing is an important process that helps to meet the growing demand for calcite powder in various industries.

Bureau du siège social

WhatsApp:+8615225176731

E-mail: [email protected]

Adresse: Non. 1688, Gaoke East Road, Nouveau quartier de Pudong, Shangai, Chine.

Site Internet: https://www.mill-sbm.com/

Contenu des articles

Messages récents

- Crusher à mâchoire pour le traitement du calcaire: Un guide de l'efficacitéComme le calcaire est largement utilisé dans la construction et l'industrie, Son traitement nécessite un broyeur de mâchoire solide et durable pour répondre aux besoins de l'industrie. Parmi les nombreux concasseurs, La mâchoire…

- Impact Crusher avec 300 TPH pour les grands projetsLorsque les géants miniers font face à des montagnes de minerai de fer ou de démolitions urbaines, génèrent des avalanches en béton, 300 TPH Impact Crusher apparaît comme des titans de transformation des matériaux. Au-delà des spécifications de base, Nous disséquons comment ces industriels…

- Broyeur à impact abordable: Un changement de jeu pour les petites entreprises de constructionLes petites entreprises de construction sont souvent confrontées à des contraintes budgétaires, pourtant besoin d'équipement fiable – Un concasseur à impact abordable. Ce broyeur peut combler l'écart, fournir un traitement de matériaux efficace sans un énorme capital…