E-mail: sales@mill-sbm.com

Crushers dans la production globale: Équipement clé et meilleures pratiques

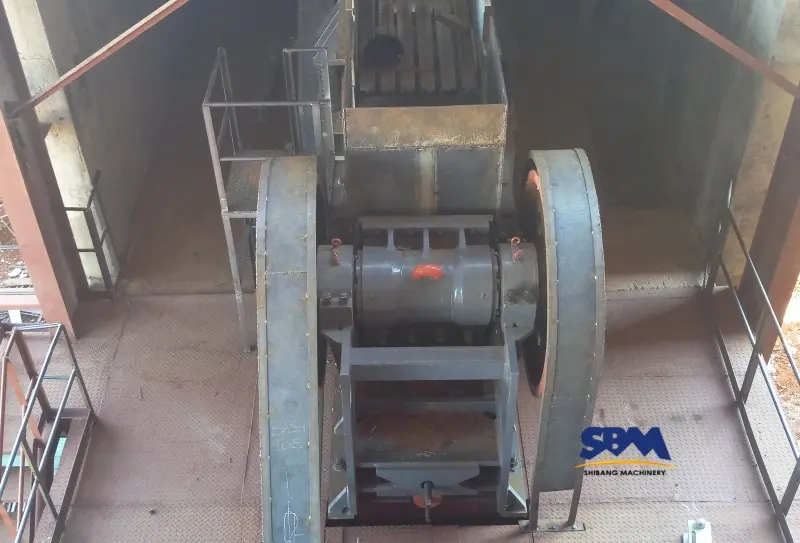

La construction moderne repose sur des agrégats transformés efficacement, rendre les concasseurs indispensables dans les opérations minières et carrières (production globale). Ce guide examine les applications internationales de la technologie écrasante, Stratégies de sélection de l'équipement, et les informations de maintenance à travers de vrais exemples.

Études de cas mondial: Crushing Solutions in Action

1. German Quarry Upgrades to Hybrid Jaw Crushers

The Bavarian Aggregate production Group reduced energy consumption by 22% after implementing concasseurs à mâchoires with adaptive crushing chambers. Their limestone operation now achieves 650 TPH while maintaining <5% oversize material.

2. Australian Mobile Crushers Revolutionize Remote Sites

Rio Tinto’s Pilbara iron ore project utilizes mobile jaw crushers that process 800 tonnes / heure. The track-mounted units reduced transport costs by 40% compared to stationary plants.

3. Canadian Recycled Concrete Processing Breakthrough

Toronto’s GreenDemolition Inc. employs impact-jaw combi-crushers to achieve 98% purity in recycled aggregates. Their system recovers 12,000 tons/month of construction waste.

Core Equipment Selection Strategies

Balancing Power and Precision in Crusher Choice

When choosing jaw crushers in aggregate production, consider:

- Feed size vs. gape width ratio (ideal 0.8:1)

- CSS (Closed Side Setting) adjustment range

- Toggle plate safety mechanism types

SBM C6X200 units in Swedish granite quarries demonstrate how 1,200 mm feed openings handle 800-1,000 MPa materials effectively.

Maintenance Mastery: Extending Crusher Lifespan

Smart Liner Management Techniques

Proper jaw crusher liner replacement protocols can increase service life by 30%:

- Monitor wear patterns using 3D scanning (adopted by Chilean copper mines)

- Implement symmetrical rotation schedules

- Use manganese steel alloys (14-18% Mn content)

South African platinum mines report 6-month liner cycles instead of 4-month replacements through optimized maintenance.

Emerging Technologies Shaping Aggregate Crushing

AI-Powered Crushing Optimization

’s crushing system in Nevada gold mines uses real-time ore analysis to automatically adjust crusher settings, boosting throughput by 18%.

Eco-Crushers: Noise and Dust Reduction

Eco-crushers features:

- 360° dust encapsulation

- 72 dB noise rating (vs standard 110 dB)

- Hybrid diesel-electric power options

Future Outlook:

The global aggregate crushers market in aggregate production (valued at $5.2B in 2023) is projected to grow at 5.8% CAGR through 2030 (Global Market Insights). Mobile and hybrid systems will dominate, particularly in infrastructure projects across Southeast Asia and Africa.

Practical Tip: Always cross-reference crusher capacity charts with actual material bulk density. Volcanic rock operators in Indonesia improved efficiency by 15% after adjusting for 1.8 t/m³ material density vs standard 1.6 t/m³ assumptions.

This comprehensive approach to crushing system design – combining appropriate equipment selection, proactive maintenance, and technology adoption – ensures optimal aggregate production outcomes across diverse operational contexts.

Bureau du siège social

WhatsApp:+8615225176731

E-mail: sales@mill-sbm.com

Adresse: Non. 1688, Gaoke East Road, Nouveau quartier de Pudong, Shangai, Chine.

Site Internet: https://www.mill-sbm.com/

Contenu des articles

Messages récents

- Quels sont les modèles de concasseur en pierre les plus efficaces?Faire correspondre vos modèles de concasseur en pierre n'est pas seulement efficace - il s'agit de résoudre les goulots d'étranglement opérationnels. Équipement SBM China, Comme la série HP pour Hard Rock Mining ou le K3…

- Applications de broyeur à la mâchoire dans le traitement agricole du calcaireDes Prairies du Midwest aux paddies d'Asie du Sud-Est, Le calcaire écrasé respire la vie dans les terres agricoles acides - mais débloquant ses exigences potentielles à pleine mâchoires conçues pour lutter contre les formations rocheuses régionales, Équilibrer le pouvoir avec…

- Traitement du minerai d'or: Efficacité du broyeur à la mâchoireTraitement efficace du minerai d'or charnise sur des opérations de concassage précises, où les broyeurs de mâchoire convertissent les dépôts robustes en matières premières optimisées. Découvrez comment affiner ces machines pour une productivité maximale sans compromettre le site de travail…