E-mail: [email protected]

Crusher à mâchoire fixe vs broyeur gyratoire: Quel est le meilleur choix pour votre projet?

Lors de la sélection de l'équipement de concassage primaire, the debate betweenfixed jaw crusher contregyratory crusher often arises. Les deux machines excellent dans la réduction des grosses roches mais diffèrent considérablement dans la conception, efficacité, et application. This guide breaks down their differences, real-world use cases, and how to choose the right crusher for projects likerecyclage du béton or mining.

Core Design Differences: How They Work

Fixed Jaw Crusher Structure

UNfixed jaw crusher operates using compressive force. Its two vertical jaws—one stationary (fixed) and one movable—crush materials by pressing them until they break. Models like thePE 600 × 9000000000000000 are popular for their simplicity and reliability in quarries.

Gyratory Crusher Mechanics

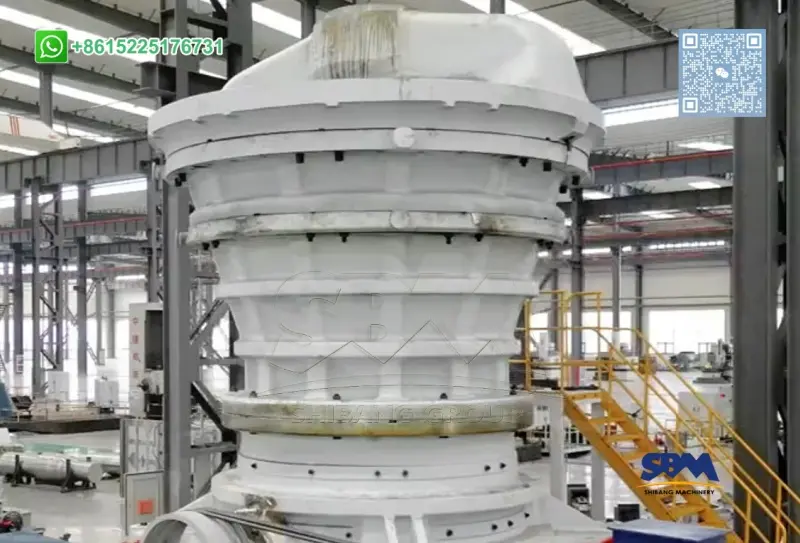

Broyeurs gyratoires use a rotating mantle and concave surfaces. The central spindle gyrates, creating a compressive action that crushes materials. These machines are taller and bulkier, making them ideal for high-capacity mining operations.

Performance Comparison: Efficacité & Sortir

Crushing Capacity

- Fixed jaw crushers: Best for medium-scale projects likerecyclage du béton or aggregate production. They handle abrasive materials well but require frequent maintenance.

- Broyeurs gyratoires: Higher throughput (jusqu'à 14,000 e) suits large mining operations. Their continuous crushing cycle reduces downtime.

Consommation d'énergie

Gyratory crushers consume 15–20% less energy per ton in high-capacity settings. Cependant, smaller operations may preferCrushers de la mâchoire fixes like theCrusher à mâchoire mobile vs broyeur à mâchoire fixe for lower upfront costs.

Entretien & Coûts opérationnels

Wear Parts Replacement

- Fixed jaw crushers: Cheaper to maintain. Replaceable parts like toggle plates and liners are accessible.

- Broyeurs gyratoires: Complex assembly increases downtime during mantle or concave replacements.

Longevity

Gyratory crushers last longer under heavy-duty conditions, whileconcasseurs à mâchoires like thePE 600×900 offer cost-effective solutions for shorter projects.

Études de cas mondial: Where Each Crusher Shines

Cas 1: Concrete Recycling in Germany

A Berlin-based recycling plant opted for afixed jaw crusher to process demolition waste. Its compact design and easy integration with screening systems streamlined theirrecyclage du béton workflow.

Cas 2: Copper Mining in Chile

A Chilean mine uses a gyratory crusher to process 12,000 tons of ore daily. En même temps, the machine’s high capacity and low energy use reduced operational costs by 22%.

How to Choose Between Them

Consider these factors:

- Project Scale: Small to medium? Pick afixed jaw crusher. Large mining? Opt for gyratory.

- Material Hardness: Abrasive aggregates? Jaw crushers perform better.

- Budget: Gyratory crushers have higher upfront costs but lower long-term expenses.

For mobile setups, exploreCrusher à mâchoire mobile vs broyeur à mâchoire fixe comparisons.

Final Thoughts

Bothfixed jaw crusher contregyratory crusher have unique strengths. While jaw crushers dominaterecyclage du béton and mid-sized quarries, gyratory models excel in high-volume mining. Assess your project’s needs, material type, and budget to make an informed choice.

Need a reliable crusher? Learn more about our PE 600 × 9000000000000000 or explore our guide to gyratory crushers for industrial applications.

Bureau du siège social

WhatsApp:+8615225176731

E-mail: [email protected]

Adresse: Non. 1688, Gaoke East Road, Nouveau quartier de Pudong, Shangai, Chine.

Site Internet: https://www.mill-sbm.com/

Contenu des articles

Messages récents

- Crusher à mâchoire pour le traitement du calcaire: Un guide de l'efficacitéComme le calcaire est largement utilisé dans la construction et l'industrie, Son traitement nécessite un broyeur de mâchoire solide et durable pour répondre aux besoins de l'industrie. Parmi les nombreux concasseurs, La mâchoire…

- Impact Crusher avec 300 TPH pour les grands projetsLorsque les géants miniers font face à des montagnes de minerai de fer ou de démolitions urbaines, génèrent des avalanches en béton, 300 TPH Impact Crusher apparaît comme des titans de transformation des matériaux. Au-delà des spécifications de base, Nous disséquons comment ces industriels…

- Broyeur à impact abordable: Un changement de jeu pour les petites entreprises de constructionLes petites entreprises de construction sont souvent confrontées à des contraintes budgétaires, pourtant besoin d'équipement fiable – Un concasseur à impact abordable. Ce broyeur peut combler l'écart, fournir un traitement de matériaux efficace sans un énorme capital…