E-mail: [email protected]

Guide de sélection des plaques de mâchoire: Optimiser les performances pour votre opération de concassage

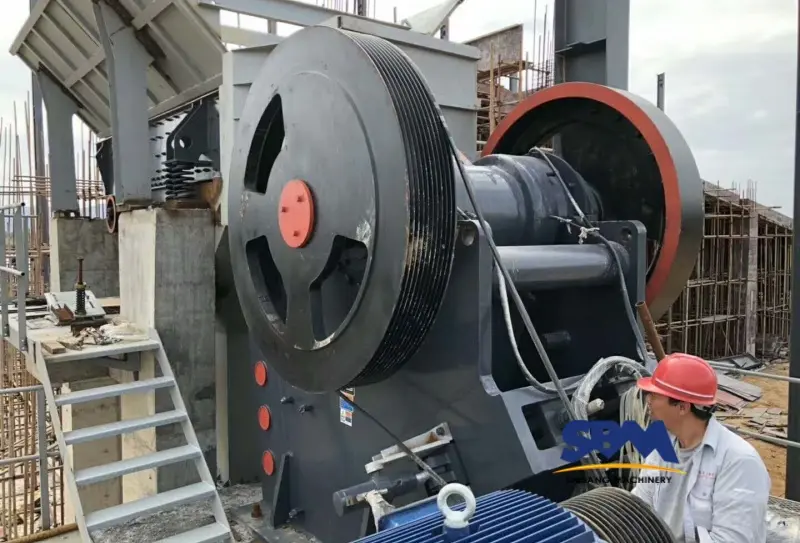

Choosing the right jaw plates can increase yourefficacité de concassage by 25-40% while reducing replacement costs. This comprehensivejaw plate selection guide explains how material composition, tooth profile design, and operating conditions determine plate longevity. Whether you’re operating a C6X Jaw Crusher or older models, these insights will help you make informed decisions.

Key Factors in Jaw Plate Selection

Material Composition Choices

Modern jaw plates use three primary materials:

- Manganese Steel (14-18%): Ideal for general-purposequarry applications, withstands 50-70k tons before replacement

- Chrome Iron Alloy: 30% longer lifespan in abrasive materials like granite

- Ceramic-Enhanced: Reduces wear by 45% in high-silica content operations

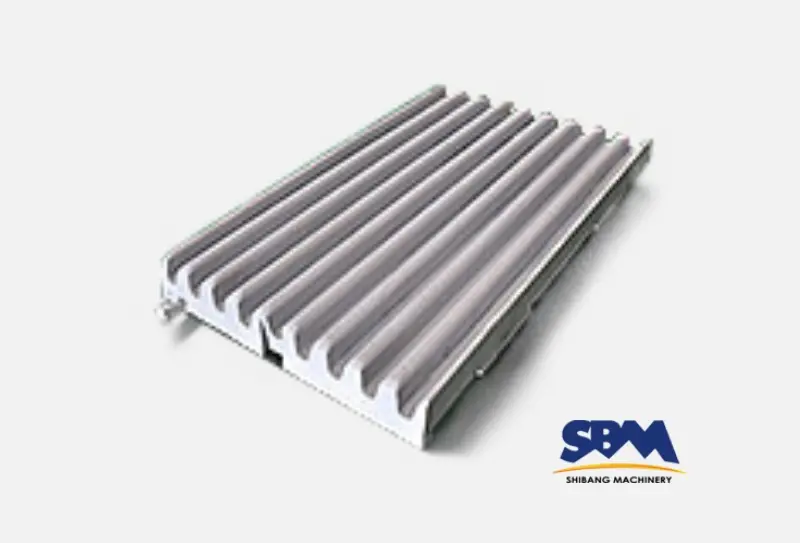

Tooth Profile Design Considerations

The plate’s tooth configuration directly impacts yourcrusher’s working mechanism:

| Profile Type | Best For | Output Size Range |

|---|---|---|

| Straight | Primary crushing | 150-300 millimètre |

| Waved | Secondary reduction | 50-120 millimètre |

| Hybrid | Mixed material feeds | 30-150 millimètre |

4-Step Selection Process

- Analyze Feed Material: Test hardness (Échelle de Mohs) and abrasiveness

- Determine Crusher Type: C6X series jaw crusher requires specific plate locking systems

- Calculate Economic Lifespan: Balance initial cost vs tons crushed/$

- Verify Compatibility: Check mounting system dimensions (±2mm tolerance)

Maintenance Synergy: Plates and Crusher Health

Properjaw crusher maintenance extends plate lifespan by 60%:

- Plaques de rotation 200-300 heures d'opération

- Maintain correct CSS settings (affects wear patterns)

- Use laser alignment tools for precise installation

Étude de cas: Granite Quarry Optimization

A Brazilian operation achieved 32% cost reduction by:

- Switching from standard Mn14 to Mn18Cr2 plates

- Implementing bi-weekly wear measurements

- Syncing replacements with scheduled maintenance downtime

Techniques de surveillance avancées

- 3D wear scanning for precise remaining thickness analysis

- AI-powered wear rate prediction models

- Ultrasonic hardness testing for material verification

Common Selection Mistakes

- Choosing cheap plates needing 3x more frequent replacement

- Ignoring material compatibility (e.g., zinc contamination)

- Overlooking plate weight impacts on crusher kinematics

Strategic Selection Pays Dividends

Masteringjaw plate selection requires understanding your material, machine type (like C6X models), and operational goals. Pair this guide with regular preventive maintenance to achieve 18-24 month plate lifespans even in demanding conditions. Remember: The optimal plate today may differ tomorrow – re-evaluate selections with major material changes.

Bureau du siège social

WhatsApp:+8615225176731

E-mail: [email protected]

Adresse: Non. 1688, Gaoke East Road, Nouveau quartier de Pudong, Shangai, Chine.

Site Internet: https://www.mill-sbm.com/

Contenu des articles

Messages récents

- Why Jaw Crushers Are the Unshakable Foundation of Mining?In the rugged world of mining, where efficiency determines profitability, jaw crushers stand as the first line of defense against raw, unprocessed ore. From Australia’s iron-rich Pilbara region to Argentina’s…

- What Industries Primarily Use Jaw Crushers? A Global PerspectiveThe applications of jaw crushers are very wide and numerous industries mainly use them. While jaw crushers might seem like simple mechanical workhorses, their impact on modern industry is anything…

- Understanding the Key Components of Impact Crushers for Optimal Crushing EfficiencyThis guide explores the key components of impact crushers, their functions, and real-world applications in global industries. Key Components of Impact Crushers 1. Rotor Assembly: The Heart of Crushing Efficiency…