E-mail: [email protected]

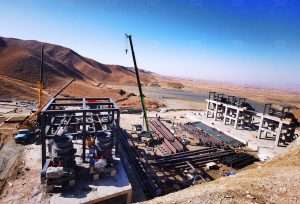

Usine de concassage de déchets solides

Après avoir soigneusement examiné la force et l'équipement, l'entreprise, en collaboration avec le comité municipal du parti et le gouvernement, a choisi de coopérer avec SBM pour construire un projet d'usine de concassage de déchets solides de construction afin d'atténuer la pression des déchets de construction.

Profil de projet

- Matière première:Déchets de construction (de la démolition, Bloc de décoration et de béton)

- Capacité:100e

- Taille de sortie:0-5-10-31.5millimètre

- Applications:Utilisé pour fabriquer des agrégats recyclés

- Équipement majeur:Concasseur à percussion CI5X, Crible vibrant S5X, Convoyeur à bande B6X, Plateforme MS Steel

Avantages

- Le couvercle à poussière du convoyeur à courroie traditionnel est en acier coloré et en carreaux, ce qui n'est pas seulement facile à endommager, mais a également un mauvais effet de protection de l'environnement. Mais dans ce projet, SBM adopte une couverture de poussière de flexion entièrement en acier, qui est beau, et atmosphérique, une longue durée de vie et une meilleure performance de protection de l'environnement.

- Le projet de déchets solides, la plante écrasante est équipé de CI5X Impact Crusher, qui est une machine avancée pour éliminer les déchets solides. Les déchets de construction sont traités par le processus de “écrasement et tri + recyclage” pour produire des agrégats recyclés (y compris le sable recyclé et les matériaux en briques recyclées). Ainsi, la sortie quotidienne peut être à la hauteur 1,200 tonnes, avec une sortie annuelle d'environ 400,000 M3 (pour les briques recyclées).

- La base de l'équipement principal adopte une structure entièrement en acier (Peut être préparé à l'avance puis directement assemblé sur le site), ce qui augmente considérablement la vitesse de la construction du projet et assure la qualité globale de la plante entière.

- Le projet a été achevé à la fin de 2019, mais pas mis en service à cause de Covid-19. Quand en avril 2020, L'épidémie a été maîtrisée. Nos ingénieurs se sont immédiatement précipités sur le site pour guider la mise en service, Promouvoir la production de reprise.