Surel: [email protected]

Bagaimana cara kerja penghancur rahang?

Before we understand “how does jaw crusher work?”, we need to understand what is a jaw crusher and the basic components of a jaw crusher. Then let’s take a look at the types of jaw breakers.

What is a jaw crusher?

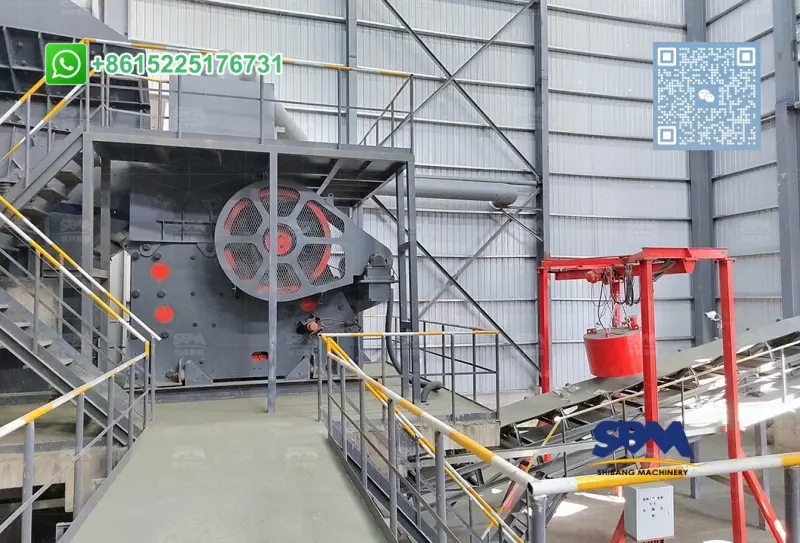

Jaw crusher is a commonly used mining machinery and equipment, which crushes larger stones or ores through the mutual extrusion of fixed jaws and movable jaws. Its main function is to reduce the size of mined ore for processing or transportation. Jaw crushers (for sale) are used to great effect in mines and quarries as well as in recycling processes where the reduction of bulky materials is required. The crushing equipment is widely used in mining, metalurgi, bahan bangunan, construction and other industries.

Basic components of jaw crusher

- Fixed jaw and movable jaw

- Jaw liner

- Eccentric shaft

- Drive pulley

- Bracket

How does a jaw crusher work?

After having a basic understanding of the jaw crusher machine, let’s see how the jaw crusher works.

Feeding stage

The ore or rock to be crushed enters the crushing chamber (the volume or cavity between the two jaws) through the vibrating grid feeder. The power provided by the motor rotates the eccentric shaft. As the eccentric shaft rotates, the movable jaw reciprocates.

Crushing stage

At this time, the ore or rock enters the crushing chamber. The movable jaw begins to exert pressure on the rock in the crushing chamber. The ore is squeezed into smaller pieces and gradually flows down to the lower discharge port.

Discharging stage

After the ore is crushed to a set size, it is discharged from the crushing chamber through the lower discharge port. The size of the final product can be pre-set.

How to adjust the discharge size?

Use wedges or hydraulic systems to adjust the gap between the two jaws.

SBM jaw crushers include safety features such as toggle plates. It protects the crusher from overload or uncrushable materials. Jaw crushers are heavy machines, so regular maintenance ensures that the jaw crusher operates efficiently. Maintenance operations include lubricating bearings, checking jaw wear, and tightening or replacing any loose or worn parts.

Types of Jaw Crusher

Penghancur Rahang PE

Sebagai penghancur primer klasik dengan kinerja stabil, PE Jaw Crusher banyak digunakan untuk menghancurkan bijih logam dan non logam serta agregat bangunan atau untuk membuat pasir buatan.

PEW Jaw Crusher

PEW Jaw Crusher merupakan mesin penghancur baru yang dikembangkan oleh SBM, produsen penghancur rahang, setelah rilis jaw crusher tradisional. Di samping itu, this jaw crusher is a perfect combination of modern science and technology and the production practice, yang dapat lebih memenuhi permintaan produksi otomatis dari banyak pelanggan.

Penghancur Rahang C6X

Semua indeks C6X Jaw Crusher pada struktur dan efisiensi produksi menghadirkan teknologi modern yang canggih. Jadi, SBM’s C6X Jaw Crusher can solve such problems of the existing universal jaw crushers as low production efficiency, pemasangan dan pemeliharaan yang sulit. Saat sekarang, C6X Jaw Crusher adalah mesin penghancur kasar yang ideal di pasar domestik.

Kantor Pusat

ada apa:+8615225176731

Surel: [email protected]

Alamat: TIDAK. 1688, Jalan Timur Gaoke, Kabupaten baru Pudong, Shanghai, Cina.

Situs web: https://www.mill-sbm.com/

Isi Artikel

Tulisan Terbaru

- Memperbaiki penghancur rahang untuk pemrosesan scheelite: Panduan komprehensifSchelite, Sumber kritis tungsten, menuntut peralatan pemrosesan yang kuat (Memperbaiki penghancur rahang) karena kekerasan dan sifatnya yang abrasif. Fixed Jaw Crushers telah muncul sebagai landasan di scheelite…

- Analisis getaran crusher rahang tetap: Meningkatkan kinerja dan umur panjangAnalisis getaran adalah alat penting untuk memastikan keandalan dan efisiensi crusher rahang tetap di industri pertambangan dan konstruksi. Dengan memantau dan menafsirkan pola getaran, Operator dapat mendeteksi…

- Kapasitas crusher rahang tetap tidak terkunci: Dari granit Kanada ke bijih besi AustraliaSaat tambang besi Lac Bloom Quebec perlu mencapai 650tph secara konsisten, Pengaturan crusher rahang tetap mereka menjadi pahlawan - berprestasi 93% uptime melalui manajemen kapasitas cerdas. Panduan ini memecah rahang tetap…