Surel: sales@mill-sbm.com

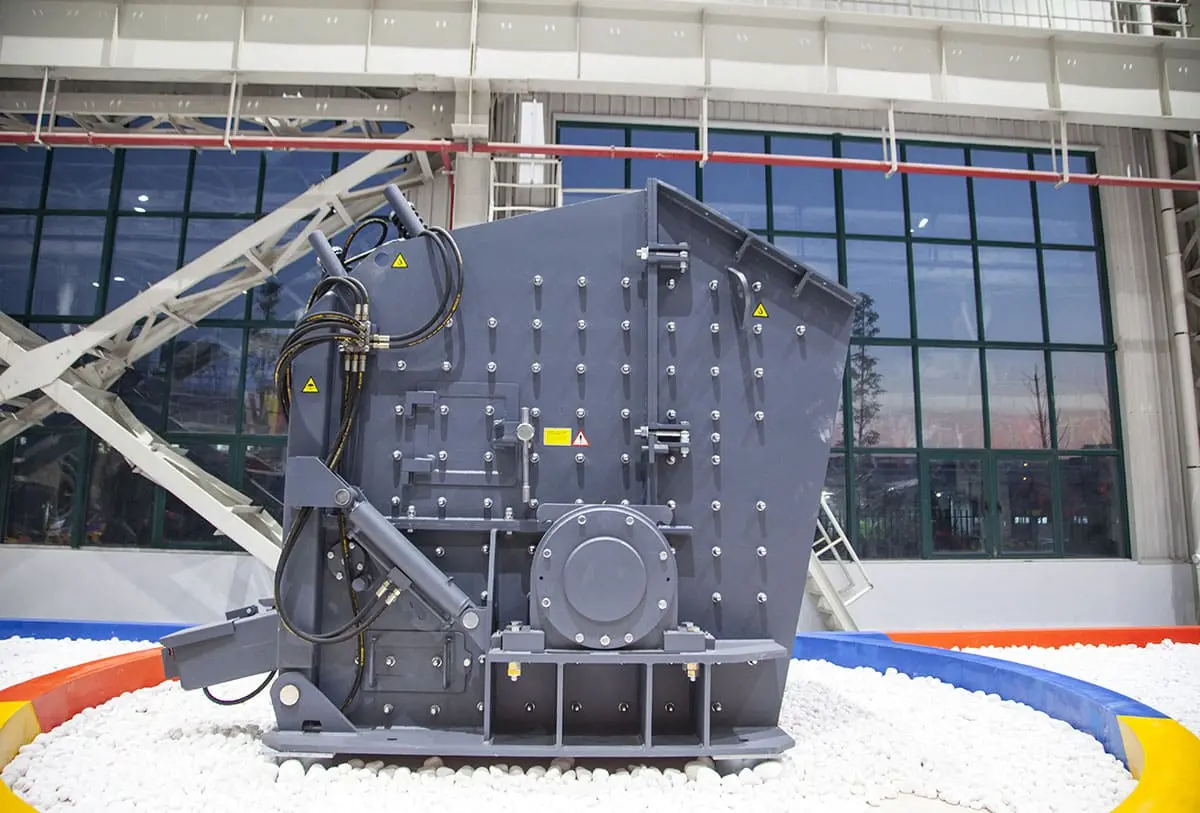

Penghancur Dampak PFW

Penghancur Dampak PFW (Juga dikenal sebagai “Penghancur Dampak Eropa”) terutama digunakan dalam metalurgi, milikku, semen, teknik Kimia, bahan tahan api, keramik dan industri lainnya, serta dalam pembangunan jalan tol, proyek pemeliharaan air, agregat dan ladang pasir buatan mesin, dll..

Fitur Produk: Penggunaan perangkat jacking hidrolik otomatis membuat pemeriksaan dan pemeliharaan lebih mudah serta mengurangi biaya tenaga kerja.

- Ukuran Masukan: 0-700mm

- Kapasitas: 70-400TPH

- Bahan: Batu gamping, feldspar, kalsit, talek, barit, dolomit, kaolin, gips, grafit, dll..

Teknologi Teratas, Desain Unik

PFW Impact Crusher mengadopsi teknologi produksi kelas dunia. Itu terbuat dari bahan kelas atas. Desain rotor tugas berat dan pemeriksaan yang ketat memungkinkan rotor memiliki kualitas tinggi. Sementara itu, perangkat tetap yang unik membuat palu lebih andal.

Struktur Baja Cor, Kapasitas Penampungan Tinggi

Kursi bantalan PFW Impact Crusher menggunakan struktur baja cor integral, yang menjamin operasi yang stabil. Bantalan yang lebih besar mempunyai kapasitas penahan yang lebih tinggi.

Pengoperasian semi-otomatis Membuat Perawatan Mudah dan Nyaman

PFW Impact Crusher dapat melengkapi sistem kontrol hidrolik. Oleh perangkat hidrolik, ukuran bukaan pelepasan dan granularitas pemakaian dapat dikontrol dengan cepat. Di samping itu, perangkat dongkrak hidrolik otomatis berguna untuk penggantian bagian yang rentan seperti palu dengan cepat sehingga waktu henti pemeliharaan dapat dipersingkat secara tidak langsung.

Proses Teknologi yang Disederhanakan, Aplikasi Luas

Penghancuran dua rongga pada PFW Impact Crusher dapat menyederhanakan proses teknologi penghancuran kasar dan sedang, sedangkan penghancuran tiga rongga membuat PFW Impact Crusher berkinerja sangat baik dalam penghancuran halus dan prima.. Dua jenis rongga penghancur dapat memenuhi sebagian besar butiran kasar, operasi penghancuran sedang dan halus.

Pemrosesan Digital, Presisi Lebih Tinggi

Ada puluhan baris alat mesin pengontrol numerik. Operasi seperti pelat baja’ pemotongan, pembengkokan, perencanaan, penggilingan dan penyemprotan cat semuanya dikontrol secara numerik. Presisi pemesinan tinggi, terutama untuk bagian inti.

Pasokan Suku Cadang yang Cukup, Operasi Tanpa Khawatir

SBM, yang usahanya meliputi produksi dan penjualan, bertanggung jawab atas setiap mesin yang diproduksi oleh diri kita sendiri. Kami dapat menawarkan pelanggan layanan teknis tentang produk dan suku cadang asli untuk memastikan pengoperasian tanpa rasa khawatir.

Prinsip bekerja

PFW Impact Crusher menghancurkan material dengan kekuatan tumbukan. Saat material memasuki area kerja palu, benda-benda tersebut mungkin hancur akibat guncangan berkecepatan tinggi dan kemudian dilemparkan ke perangkat tumbukan di atas rotor untuk dihancurkan lagi. Berikutnya, bahan memantul dari pelat pelapis ke area kerja palu lagi. Proses ini berulang terus menerus sampai bahan mencapai granularitas yang memenuhi syarat dan dibuang. Menyesuaikan jarak antara rak tumbukan dan rak rotor dapat mengubah butiran dan bentuk produk jadi. Di belakang pelat tumbukan terdapat alat pengaman pegas. Ketika bahan yang tidak mudah pecah memasuki ruang penghancur, rak tumbukan bergerak mundur untuk mengeluarkan material yang tidak mudah pecah dari penghancur.

Parameter Produk

| Model | Spesifikasi rotor (mm) | Pembukaan umpan (mm) | Ukuran makan maksimum (mm) | Kapasitas(th) | Kekuatan(kW) | Dimensi keseluruhan (mm) |

| PFW1214Ⅲ | Ф1150×1400 | 570×1430 | 250 | 90-170 | 132 | 2550×2310×2100 |

| PFW1315Ⅲ | Ф1300×1500 | 625×1530 | 300 | 180-270 | 200 | 2960×2570×2380 |

| PFW1415Ⅲ | Ф1400×1500 | 800×1530 | 350 | 280-350 | 250-315 | 3120×2650×2660 |

Catatan:

Gambar produk dan parameter tentang model, data, performa dan spesifikasi di situs web ini hanya untuk referensi. Ada kemungkinan SBM dapat melakukan perubahan atas informasi tersebut di atas. Untuk pesan tertentu, silakan merujuk ke objek nyata dan manual pengguna. Tanpa instruksi khusus, SBM berhak untuk menjelaskan semua data yang terlibat dalam website ini.