Имэйл: [email protected]

Оновчтой бутлах үр ашгийг оновчтой болгохын тулд нөлөөллийн бутлуурын гол бүрэлдэхүүн хэсгүүдийг ойлгох

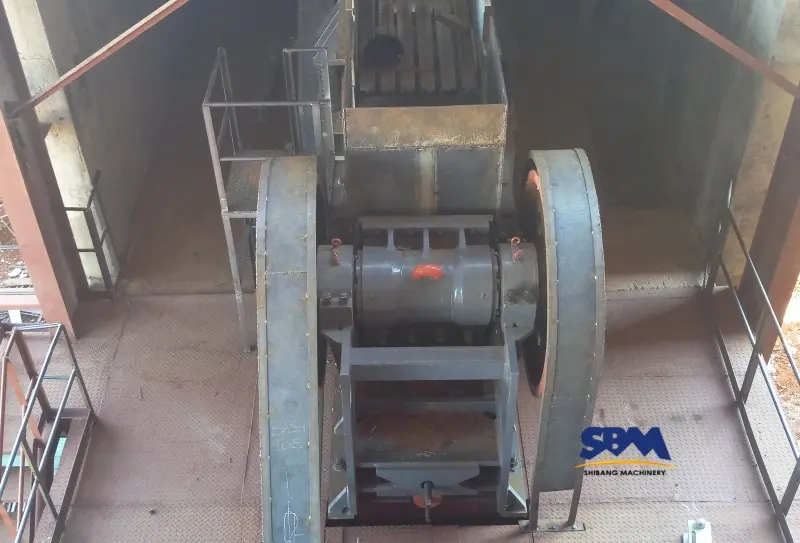

Энэхүү гарын авлага нь нөлөөллийн бутлуурын гол бүрэлдэхүүн хэсгүүдийг судалж үздэг, тэдний функцууд, дэлхийн үйлдвэрлэлийн бодит програмууд.

Нөлөөллийн бутлуурын гол бүрэлдэхүүн хэсгүүд

1. Ротор угсралт: Үр ашгийг бутлах зүрх

Ротор бол материалыг бутлахад шаардагдах хүчийг үүсгэдэг төв эргэдэг элемент юм. Алхаар тоноглогдсон эсвэл цохих баараар тоноглогдсон, Энэ нь ирж буй тэжээлийг цохихын тулд өндөр хурдаар эргэлддэг. Жишээ нь, нь Vsi6x элс хийх машин (100-583 тонн / тонн цаг) элэгсэгт тэсвэртэй хайлштай хүнд даацын роторыг ашигладаг, Их Британийн карьеруудын бороохой боловсруулахад тохиромжтой.

Гол онцлог:

- Блок баар: Роторт хавсаргасан металл баарыг сольж болно.

- Дээлтийн диск: Аюулгүй цохилт ба баланс ба балансын эргэлт.

2. Хормогч, сараалжтай нөлөөлдөг: Эцсийн бүтээгдэхүүнийг хэлбэржүүлэх

Хормогч хормогч (эсвэл таслагч хавтан) бутлах камер, Хоёрдогч мөргөлдөөний материалыг дахин чиглүүлэх. Тохируулж болох GRANS Хяналтын гаралтын хэмжээ, жигд байдлыг хангах. Ашиглан Германы дахин боловсруулах үйлдвэр Vsi crusher (60-520 тонн / цаг) тайлагнасан a 30% Хормогч цоорхойг оновчтой болгох замаар SLAG дахин боловсруулах үр ашгийг сайжруулах.

3. Контаторийн систем: Хийн гүйцэтгэлийн гүйцэтгэл

Мотор, бүс / Динол систем нь роторыг жолооддог. Өндөр момент мотор, шиг 315 kw нэгж нь Гурав дахь Крусер, АНУ-д хатуу чулуулгийг тууштай бутлах боломжийг идэвхжүүлэх. уул уурхайн үйл ажиллагаа.

4. Орон сууц, хүрээ: Дарамт шахалтанд тэсвэртэй байдал

Crusher-ийн гаднах бүтэц нь туйлын хүчийг тэсвэрлэдэг. Залхуу ган хүрээ, гэх мэт Үндсэн нөлөөллийн бутлуур, Өндөр түвшний үйл ажиллагааны үед тогтвортой байдлыг хангах.

Глобал хэрэглээний бутлуурын хэрэглэгчид

Хэрэгжүүлэх Сандал 1: Герман дахь Slag дахин боловсруулалтыг дахин боловсруулав

Dortmund ашигладаг ган үйлдвэр a PFW нөлөөллийн бутлуур боловсруулах 400 өдөр бүр тонн slag. Тохируулж болох хормогч ба tungsten Carbide Blow баар нь өмсөхийг багасгадаг, боломжтой хүр 95% материалыг дахин ашиглах.

Хэрэгжүүлэх Сандал 2: Австралид рокийг хэрхэн үр дүнтэй бутлах вэ

Квинсландын карьер нь ажилд авдаг CI5x нөлөөллийн бутлуур замын суурь дүүргэгчийг үйлдвэрлэхийн тулд олон функциональ ротортой. Түүний 585 тонн / цаг хүчин чадал нь үйл ажиллагааны зардлыг бууруулдаг 20%.

Урт наслах засварын зөвлөмжүүд

- Цэврүү баарыг тогтмол шалгаж байгаарай: Бутлах үр ашгийг хадгалахын тулд өмссөн баарыг солих.

- Тослох материалыг тослох: Drive системд хэт халахаас урьдчилан сэргийлэх.

- Хормогч цоорхойг тохируулах: Хязгаарлалт эсвэл дахин боловсруулсан бетонон шиг тодорхой материалын гаралтын хэмжээг оновчтой болгох.

Дүгнэлт: Нөлөөллийн сүйрэл гүйцэтгэлийг оновчтой болгох

Ротороос орон сууц руу, нөлөөллийн кручинд зориулсан гол бүрэлдэхүүн хэсгүүд нь материаллаг боловсруулалтад чухал үүрэг гүйцэтгэдэг. Төлөө Шалцуулах дахин боловсруулалт гаргах эсвэл хадсан хутга, PF гэх мэт зөв нөлөөллийн crusher загварыг сонгох, Pfw, Ci5x, БҮГД, VSI5X эсвэл VSI6X-АЖИЛЛАГАА АЖИЛЛАГАА, АЖИЛЛАГАА, АЖИЛЛАГАА АЖИЛЛАГАА. Тохирсон шийдлийн хувьд, Манай гарын авлагыг судлах бутлах үр ашиг болон Чулууг хэрхэн бутлах вэ үр дүнтэй.

Төв оффис

Whatsapp:+8615225176731

Имэйл: [email protected]

Хаяг: Үгүй. 1688, Гаоке зүүн зам, Пудонг шинэ дүүрэг, Шанхай, Хятад.

Вэб сайт: https://www.mill-sbm.com/

Нийтлэлийн агуулга

Сүүлийн бичлэг

- Алтан хүдрийн боловсруулалт: Эрүүний crusher үр ашигҮр дүнтэй алтан хүдрийг нарийн бутлах үйл ажиллагаанд нугас боловсруулах, эрүүний бутлагчид Rugged хадгаламжийг оновчтой болгоход хүргэдэг. Эдгээр машинуудыг ажлын байрны ажлын байрыг эзлэхгүйгээр хэрхэн тохируулахыг олж мэдээрэй ...

- Голын хайрыг эрүү бутлуураар бутлахОрчин үеийн барилгын ажилтнууд, Голын хайрга нь замд тэсвэртэй хатуужил, дасан зохицох чадварыг өгдөг, бетон, элэгдлийн хяналт. Гэсэн хэдий ч түүний хүргэн, Тогтмол бус шинж чанар нь эрүүний Бручинг тэвчихэд зориулж барьсан машин механизмыг шаарддаг. ...

- Таны салбарт зориулж зөв эрүүний эрүүгийн хэрүүлийг хэрхэн сонгох вэ?Эрүү эрүүний crusher Crusher хэмжээг сонгох нь таамаглал биш юм. Энэ бол материаллаг динамик, үйл ажиллагааны тооцоолол юм. Хатуу рок олборлосон үйлдвэрүүд нь хот суурин газрын бетон дахин боловсруулах, Тэр ч байтугай ...