Имэйл: [email protected]

Эрүүний хэрүүл амьдрал гэж юу вэ? Судалгаа & Засвар үйлчилгээний зөвлөгөө

Эрүүний crusher-ийн үйлчилгээ нь ихэвчлэн байдаг 5-15 жил, мөн түүний амьдрал нь тоног төхөөрөмжийн эрчимтэй хэрэглээний нэгтгэгдсэн нөлөөнд автдаг, maintenance system and working environment. Take two devices with exactly the same parameters as an example: the unit deployed in a Chilean copper mine reached the scrap standard in only 6 years due to long-term high-load operation; while the same type of equipment in a Norwegian granite mine has its life extended to 18 years by optimizing the crushing ratio and regularly replacing wearing parts. This seemingly surreal life difference is not accidental, but the result of the synergy between material science principles and operation and maintenance strategies. This article will deconstruct the core variables of the full life cycle management of jaw crushers through data modeling of a global typical mine case library.

Key Factors Affecting Jaw Crusher Lifespan

1. Material Hardness and Application

When the jaw crusher processes highly abrasive rocks such as granite and basalt, the wear rate of its key components (such as the jaw plate) is significantly higher than that of equipment that processes softer materials such as limestone. Taking the gold mine crushing scenario as an example, processing ore with a high quartz content will shorten the life of the core components of the equipment by about 30%-50%. Compared with similar equipment in limestone quarries, its maintenance cycle may be shortened to 1/2 or even shorter.

This phenomenon is due to the essential differences between the two types of materials:

- Differences in physical properties: Granite/basalt has a Мох хатуулаг -ийн 6-7. They contain a higher proportion of silica (quartz content is usually above 20%). Limestone has a hardness of only 3-4;

- Different wear mechanisms: When hard rocks are crushed, more micro-cutting and fatigue spalling effects will be produced, accelerating the failure of the hardened layer on the surface of the jaw plate;

- Differences in working strength: Gold ore is often accompanied by high-strength gangue, and the crushing ratio requirement can reach 40:1, which far exceeds the conventional crushing ratio requirement of limestone.

2. Design and Component Quality

The use of high-reliability components such as AC motors and reinforced toggle plate structure can significantly improve the service life of the equipment. Taking the PE series jaw crusher as an example, its representative model PE600×900 (feed port size 600×900mm) achieves efficient crushing and long-term durability through the following designs:

- Heavy-duty frame structure: It adopts an integrated cast steel frame, combined with a zero-critical temperature annealing process, which can withstand heavy-load impact of materials with a maximum thickness of 90mm;

- Precision power system: Equipped with a 55kW AC motor, combined with servo drive technology to achieve a feeding positioning accuracy of 0.02mm;

- Intelligent adaptability: The AC drive dynamically adjusts the speed, which can adapt to changes in ore hardness and reduce energy consumption by 15-30%;

- Wear-resistant component configuration: Imported seals and anti-corrosion grease are used to extend the life of vulnerable parts such as hammers by 40%.

3. Maintenance Practices

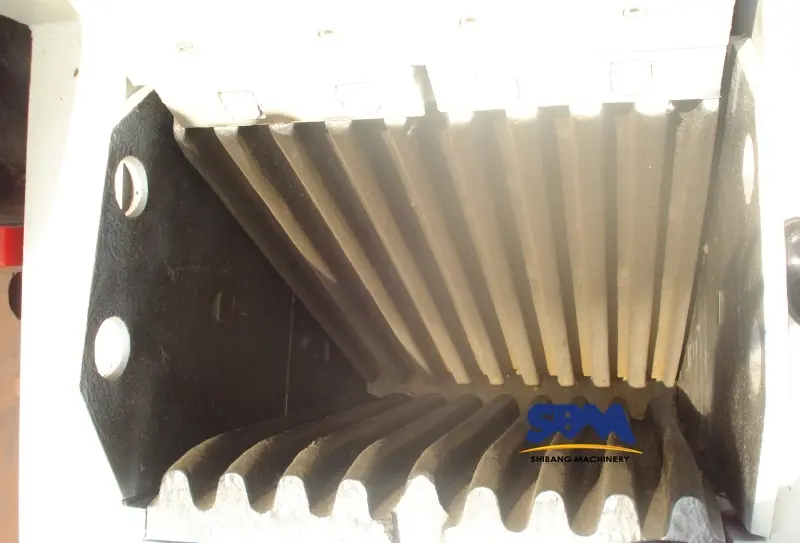

Regular lubrication, timely replacement of worn parts (Жишээ нь e., jaw plates), and monitoring of the nip angle (the angle between the fixed and movable jaws) prevent premature failure. Poorly maintained crushers in high-demand settings, like a cone crusher vs jaw crusher comparison site, often show reduced efficiency and lifespan.

4. Operational Workload

Crushers operating 24/7 in high-capacity settings, such as large-scale mining or railway projects, experience faster wear. A study of crushers in Australia’s iron ore mines revealed that units processing over 800 tons per hour required component replacements every 3–5 years.

How to Extend Your Jaw Crusher’s Life

Routine Inspections and Lubrication

Check for uneven wear on jaw plates and ensure bearings are properly lubricated. Жишээлбэл, a U.S.-based limestone quarry increased their crusher’s lifespan by 30% through biweekly inspections.

Optimize Feed Size and Speed

Overloading the crusher with oversized rocks strains the motor and frame. Use a vibrating feeder to regulate material flow, aligning with the crusher’s inlet size (Жишээ нь e., 250×400mm for smaller models).

Upgrade Wear-Resistant Components

Invest in manganese steel jaw plates for abrasive materials. A gold mine in South Africa reduced downtime by 40% after switching to hardened alloy plates.

Monitor Environmental Conditions

Dust and humidity accelerate corrosion. Install dust suppression systems in arid regions like the Middle East, where crushers face extreme environmental stress.

Case Studies: Jaw Crushers in Global Operations

Gold Mine Crusher in Canada

A jaw crusher at a Canadian gold mine processed 500 tons daily for 12 years before a major overhaul. Regular maintenance and using OEM spare parts were critical to its longevity10.

Limestone Quarry in Germany

A PE jaw crusher in a Bavarian quarry achieved a 14-year lifespan by adhering to scheduled maintenance and avoiding overloading—key lessons for operators facing similar эрүүний эрүүний хязгаарлалт in high-volume settings.

When to Consider Replacement vs. Repair

While repairs are cost-effective for minor issues (Жишээ нь e., replacing a worn toggle plate), older crushers with frequent breakdowns may warrant replacement. Жишээлбэл, upgrading to a new impact crusher with higher mining efficiency might save long-term costs in high-abrasion environments.

Дүгнэлт

The life of a jaw crusher is not a destiny, but a challenge to be overcome. The average lifespan of a jaw crusher hinges on material type, maintenance rigor, and operational demands. By adopting proactive strategies—like using wear-resistant parts and optimizing feed practices—operators can significantly extend equipment life. If you need a customized solution, please contact us. Our engineers will get in touch with you promptly. You can also compare the performance of cone crusher and jaw crusher to meet your project needs.

Төв оффис

Whatsapp:+8615225176731

Имэйл: [email protected]

Хаяг: Үгүй. 1688, Гаоке зүүн зам, Пудонг шинэ дүүрэг, Шанхай, Хятад.

Вэб сайт: https://www.mill-sbm.com/

Нийтлэлийн агуулга

Сүүлийн бичлэг

- Дан ганц сэлгэлт vs нь давхар давхуутай эрүү крадер: Хурдан харьцуулалтДүүргэгч үйлдвэрлэл, эрдэс уул уурхай гэх мэт үйлдвэрлэлийн үндсэн талбарт, нэг горимын хоорондох бүтцийн ялгаа.. Харьцуулсан ...

- Эрүүний хэрүүл амьдрал гэж юу вэ? Судалгаа & Засвар үйлчилгээний зөвлөгөөЭрүүний crusher-ийн үйлчилгээ нь ихэвчлэн байдаг 5-15 жил, мөн түүний амьдрал нь тоног төхөөрөмжийн эрчимтэй хэрэглээний нэгтгэгдсэн нөлөөнд автдаг, Засвар үйлчилгээний систем ба ажиллах ...

- Бутлахаас гадна: Хүрээлэн буй орчны нөлөөлөл, эрүүний бутлуурын шийдэлАвстралийн төмрийн хүдэрээс Норвегийн боржин чулуу, эрүүний Бручинд байгаль орчны нөлөөлөл – шуугиан, чандруу, Эрчим хүчний шаардлага ба хог хаягдал – дэлхийн мэтгэлцээн рүү очсон байна. Уул уурхайн хувьд ...