Имэйл: [email protected]

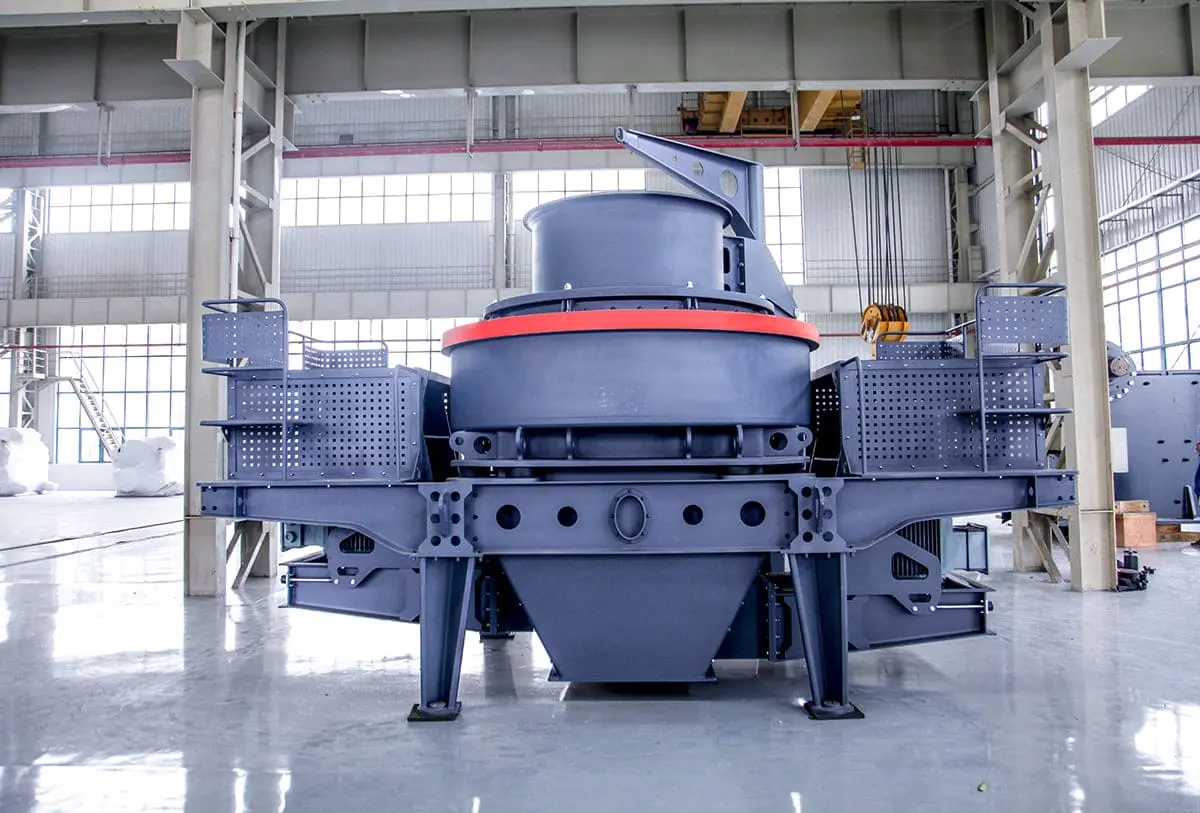

VSI6X элс хийх машин

Гэр » Бүтээгдэхүүн » VSI6X элс хийх машин

Хэмжээний зах зээлийн эрэлт нэмэгдэж байгаатай холбоотой, эрчимжүүлэх, эрчим хүчний хэмнэлт, байгаль орчныг хамгаалах, сайн чанарын машинд хийсэн элс, SBM, Хятадын мэргэжлийн элс хийх машин үйлдвэрлэгч, Уламжлалт босоо голт цохилтот бутлуурын бүтэц, үйл ажиллагааг улам оновчтой болгож, өндөр үр ашигтай, бага зардалтай элс хийх, хэлбэржүүлэх шинэ үеийн машиныг үйлдвэрлэж байна. — VSI6X элс хийх машин.

Бүтээгдэхүүний онцлог: Засвар үйлчилгээний зардал бага, эмзэг хэсгүүдийн ашиглалтын хугацааг уртасгана, илүү том хүчин чадалтай

- Оролтын хэмжээ: 0-50мм

- Хүчин чадал: 100-583TPH

- Материал: Боржин чулуу, кварц, базальт, хайрга, шохойн чулуу, доломит, гэх мэт.

Гүйцэтгэл

“Rock On Rock” Тэгээд “Төмөр дээр чулуу” Бутлах

Янз бүрийн хэрэглэгчдийн бутлах хэрэгцээг хангахын тулд, VSI6X элс хийх машин бутлах хоёр аргыг хэрэглэдэг— “чулуун дээр чулуу” болон “төмөр дээр чулуу”(үүнд хамаарна “чулуу цохих” болон “чулуу цохих төмөр” тус тус). Материалын доторлогоо “чулуун дээр чулуу” болон эсрэг блокийн бүтэц “төмөр дээр чулуу” элс хийх машины ажлын нөхцөлд тохируулан тусгайлан бүтээгдсэн, Энэ нь элс үйлдвэрлэгчийн бутлах харьцааг ихээхэн дэмждэг.

Гол хэсгүүдийн шинэ бүтцийн загварууд

Элс хийх машины ерөнхий гүйцэтгэлийг хангах зорилгоор, түүн дээрх гол хэсгүүдийг бүтэц дээрээ оновчтой болгосон, импеллер гэх мэт, холхивчийн цилиндр ба үндсэн хэсэг. SBM-ийн эзэмшдэг хэд хэдэн үндэсний патентын технологи нь өндөр ургац өгдөг, бутлах ажиллагааны өндөр үр ашигтай, бага өртөгтэй бутлах машинууд.

Ашиглалт, засвар үйлчилгээний зардал бага

VSI6X элс хийх машин нь импеллерийн зарим бүтэц, гар урлал дээр оновчтой байдаг. Зарим элэгдэж буй эд ангиудын ашиглалтын хугацаа өмнөх бутлах машинтай харьцуулахад ижил ашиглалтын нөхцөлд 30~200%-иар уртасдаг.. VSI6X босоо тэнхлэгт элс үйлдвэрлэгч нь энгийн өргөх төхөөрөмжөөр тохируулагдсан. Элс үйлдвэрлэгчид засвар үйлчилгээ шаардлагатай үед, сэнс болон холхивчийн цилиндрийг өргөхөд хэт том өргөх төхөөрөмж шаардлагагүй, элс үйлдвэрлэгчийн засвар үйлчилгээний хүндрэлийг ихээхэн бууруулдаг.

Аюулгүй, илүү найдвартай ажиллагаа

Энэхүү элс хийх машиныг зохион бүтээхдээ, аюулгүй байдал, найдвартай байдлыг харгалзан үздэг. Илүү тогтвортой, найдвартай хос хөдөлгүүртэй хөтөч, автомат шингэрүүлсэн тос тосолгооны материалыг нэгэн зэрэг нэвтрүүлсэн., Ашиглалтын аюулгүй байдал, найдвартай байдлыг хангах үүднээс gunk болон засвар үйлчилгээний платформыг оновчтой болгосон.

Тоонжуулсан боловсруулалт, Илүү өндөр нарийвчлал

Тоон хяналтын машин хэрэгслийн олон арван шугам байдаг. ган хавтан зэрэг үйл ажиллагаа’ огтлох, гулзайлгах, төлөвлөлт, тээрэмдэх, будаг шүрших зэрэг нь бүгд тоогоор хянагддаг. Машины боловсруулалтын нарийвчлал өндөр, ялангуяа үндсэн хэсгүүдийн хувьд.

Сэлбэг хэрэгслийн хангалттай хангамж, Санаа зоволтгүй ажиллагаа

SBM, бизнесүүд нь үйлдвэрлэл, борлуулалтыг хамардаг, өөрсдийн үйлдвэрлэсэн машин бүрийг хариуцдаг. Санаа зоволтгүй ажиллахын тулд бид үйлчлүүлэгчдэд бүтээгдэхүүн, анхны сэлбэг хэрэгслийн техникийн үйлчилгээг санал болгож чадна.

Ажлын зарчим

VSI6X элс хийх машин (гэж бас нэрлэдэг “Элс үйлдвэрлэгч”) хоёр тэжээлийн горимтой - “төвд хооллох” болон “төвд хооллох & талууд”. Өмнөх горимын хувьд “төвд хооллох”, Тэжээлийн бункер дээрх материалууд эхлээд төв нүхээр дамжин өндөр хурдтай ээрэх ротор руу ордог. Ротор дотор, материалыг бүрэн хурдасгаж, хөөргөх боомтоос гадагш шидээд буцсаны дараа чөлөөтэй унадаг материалын хэсэгтэй мөргөлддөг.. Дараачийн, материалууд эргэн тойрон дахь эргүүлэгтэй материалын доторлогоог цохиж (эсвэл цохилтын блок) эргүүлэг тасалгааны дотор хамтдаа. Танхимд, Материалууд эхлээд бутлах камерын дээд хэсэгт эргэлдэж, дараа нь сэнсний гүйгчээс ялгарах материал бүхий материалын хөшиг үүсгэхийн тулд доошоо хөдөлж чиглэлээ өөрчилдөг.. Эцэст нь, эцсийн бүтээгдэхүүн нь доод урсах нүхнээс гадагшилдаг. Сүүлчийн горимын тухайд “төвд хооллох & талууд”, нэгдүгээрт, тэжээлийн бункер дээрх материалууд нь дугуй нүхээр дамждаг. Дараа нь, материалыг хуваарилах тавиураар хоёр хэсэгт хуваадаг. Материалын нэг хэсэг нь өндөр хурдтай эргэдэг сэнс рүү ордог бол нөгөө хэсэг нь тавиурын бүх талаас унадаг.. Импеллер дэх материалууд хурдацтай хурдасч, тавиурын бүх талаас унасан материалтай мөргөлдөхийн тулд гадагшаа өндөр хурдтайгаар шидэгдэх болно.. Дараачийн, бүх материал нь эргэн тойрон дахь эргүүлэг материалын доторлогоог цохино (эсвэл цохилтын блок) эргүүлэг тасалгааны дотор хамтдаа. Танхимд, Материалууд эхлээд бутлах камерын дээд хэсэгт эргэлдэж, дараа нь сэнсний гүйгчээс ялгарах материал бүхий материалын хөшиг үүсгэхийн тулд доошоо хөдөлж чиглэлээ өөрчилдөг.. Эцэст нь, эцсийн бүтээгдэхүүн нь доод урсах нүхнээс гадагшилдаг.

Бүтээгдэхүүний параметрүүд

| Загвар | Зүлгүүр хийх | Дахин хэлбэржүүлэх | Зүлгүүр хийх | Дахин хэлбэржүүлэх | Хурд (эрг / мин) | Хүч (кВт) | Ерөнхий хэмжээс (мм) |

| Хамгийн их тэжээлийн хэмжээ (мм) | Дамжуулах чадвар (т/ц) | ||||||

| VSI6X8015 | 30 | 40 | 109-117 | 131-214 | 1300-1700 | 75×2 | 4100×2300×2750 |

| VSI6X9026 | 35 | 45 | 167-179 | 200-313 | 1200-1500 | 132×2 | 4200×2400×3150 |

| VSI6X1040 | 40 | 50 | 264-283 | 317-495 | 1100-1400 | 200×2 | 4880×2560×3725 |

| VSI6X1150 | 45 | 55 | 344-368 | 413-644 | 1000-1300 | 250×2 | 5500×2750×3950 |

| VSI6X1263 | 50 | 60 | 454-486 | 545-849 | 900-1200 | 315×2 | 5700×2980×4190 |

| VSI6X1380 | 50 | 60 | 601-643 | 721-1125 | 800-1100 | 400×2 | 7900×3260×4183 |

| VSI6X13100 | 50 | 60 | 751-804 | 940-1407 | 800-1100 | 500×2 | 7900×3260×4183 |

Анхаарна уу:

Загваруудын талаархи бүтээгдэхүүний зураг, параметрүүд, өгөгдөл, Энэ вэбсайт дээрх гүйцэтгэл, техникийн үзүүлэлтүүд нь зөвхөн лавлагаанд зориулагдсан болно. SBM дээр дурдсан мэдээлэлд өөрчлөлт оруулах магадлал бий. Тодорхой мессежийн хувьд, бодит объектууд болон хэрэглэгчийн гарын авлагаас лавлана уу. Тусгай зааваргүйгээр, SBM нь энэ вэбсайтад хамаарах бүх өгөгдлийг тайлбарлах эрхтэй.