ईमेल: [email protected]

जबडा क्रशर

मुख्यपृष्ठ » उत्पादने » जबडा क्रशर

Jaw crusher mainly crushes ores with large size or medium and high hardness. It has the characteristics of simple structure, high crushing efficiency and easy maintenance. It has two jaws, fixed and movable. Large pieces of material are compressed between the two jaws to become crushed stone or easy-to-handle size.

Types of Jaw Crushers / Jaw Crusher Types

There are many types of jaw crushers, each designed to meet specific crushing requirements. The main types of jaw crushers include:

Single Toggle Jaw Crusher

Single toggle jaw crusher is a type of crusher commonly used in the mining and aggregate industries. It consists of a single moving jaw that operates in an elliptical motion to crush the material between itself and the fixed jaw. This type of jaw crusher is commonly used in the primary crushing stage of various materials, such as rocks, धातू, and construction aggregates.

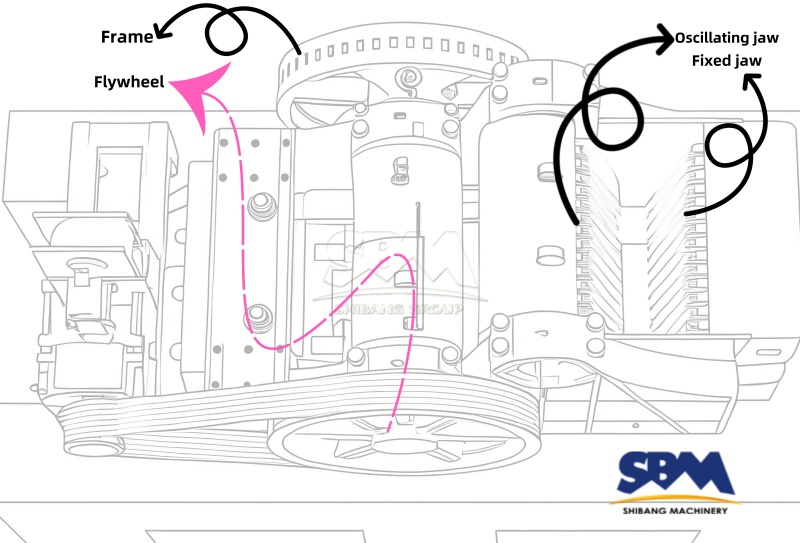

Components

| Component name | Functional description |

|---|---|

| निश्चित जबडा | The fixed part of the crusher where the material is compressed |

| Oscillating Jaw | The moving part that presses the material against the fixed jaw |

| Toggle Plate | This component connects the oscillating jaw to the main shaft and allows it to move |

| Flywheel | A large wheel that stores energy and powers the jaw movement |

| Crusher Frame | The external structure that houses all the components of the crusher |

Main Features

- Simple Design

- Efficient

- Larger feeding size

- Higher production capacity

Advantages and disadvantages comparison

| Advantages | Disadvantages |

|---|---|

| Simple construction with fewer parts | Not as suitable for harder or more abrasive materials than double toggle jaw crushers |

| Easier to maintain | Design may limit reduction ratios |

| High crushing efficiency | |

| Low power consumption | |

| Suitable for crushing large quantities |

Applications

- Mining

- Aggregate production

- Recycling operations

- Construction industry

Double-toggle jaw crusher

Double toggle jaw crushers are ideal for heavy-duty crushing jobs, especially when handling tougher materials. Its more complex mechanism, higher crushing force and increased durability make it suitable for mining, aggregate production and other demanding applications. तथापि, it requires more maintenance and has a higher initial cost compared to a single toggle jaw crusher.

Components

| Component name | Functional description |

|---|---|

| Fixed jaw | The stationary part that crushes the material |

| Oscillating jaw | The moving part that crushes the material against the fixed jaw |

| Two toggle plates | They connect the swinging jaw to the connecting rod and help create the oscillating motion required for crushing |

| Connecting rod | A shaft that moves in an elliptical motion to transmit power to the swinging jaw |

| Flywheel | A large wheel that stores energy to provide momentum for the jaw movement |

| Frame | The housing that houses all the components and provides structural support |

Main Features

- Complex Mechanism

- More Power

- More Durable

- Lower speeds

Advantages and disadvantages comparison

| Advantages | Detailed description |

|---|---|

| High reduction ratio | Double toggle jaw crushers have a higher reduction ratio, crushing tougher materials and reducing larger feed sizes more efficiently |

| टिकाऊपणा | Because the load is distributed over more parts, this type of crusher tends to be more durable and requires less frequent maintenance |

| Higher crushing efficiency | It is more efficient at handling hard and abrasive materials |

| Disadvantages | Detailed description |

|---|---|

| Higher initial cost | The double toggle mechanism makes this type of crusher more complex, with more moving parts and a higher initial cost |

| Lower throughput | The crusher operates at a lower speed compared to a single toggle jaw crusher, resulting in lower throughput |

| Higher maintenance costs | Due to the higher number of components and complex design, maintenance costs can be higher compared to a single toggle jaw |

Applications

- Mining

- Aggregate production

- Industrial applications

Compound jaw crusher

The compound jaw crusher is a versatile, efficient machine that combines the best features of single and double toggle crushers. It is particularly suitable for handling tough materials with strong crushing capacity. त्याची टिकाऊपणा, efficiency, and ability to handle a wide range of materials make it a valuable choice in the mining, बांधकाम, and aggregate production industries. तथापि, the more complex design and higher initial cost may be factors to consider when choosing this type of crusher.

Components

| Component name | Functional description |

|---|---|

| निश्चित जबडा | The fixed jaw that remains in place while the moving jaw crushes the material |

| Swinging Jaw | The moving jaw crushes the material against the fixed jaw. In a compound jaw crusher, the movement of the movable jaw can be more complex than a standard single toggle design |

| Toggle Plates | They connect the movable jaw to the connecting rod and allow for bidirectional movement |

| Connecting Rod | The shaft that transmits the mechanical force to move the movable jaw |

| Flywheel | A large wheel that stores and releases energy to assist the movement of the jaws |

| Frame | The external structure that holds all components in place and supports the crusher |

Main Features

- Combination of single and double toggle mechanism

- टिकाऊपणा

- High Crushing Capacity

- Wider Material Handling Capability

Advantages and disadvantages comparison

| Advantages | Detailed description |

|---|---|

| Efficient | The compound jaw crusher combines the advantages of single and double toggle mechanisms, making it more efficient in crushing hard materials |

| अष्टपैलुत्व | It can handle both hard and soft materials and is capable of handling larger feed sizes, making it ideal for primary crushing in various industries |

| Durable and long-lasting | The design ensures a longer service life, which reduces maintenance costs |

| Better material distribution | The design reduces stress on individual components, resulting in more even material distribution and more uniform product output |

| Disadvantages | Detailed description |

|---|---|

| Complex design and more expensive to manufacture | The combined mechanism of the compound jaw crusher makes the machine more complex and more expensive to manufacture than the simpler single toggle crusher |

| More maintenance requirements | While it can reduce wear on some components, the increased number of components can lead to more maintenance requirements |

| Higher initial cost | Due to the more complex design, the initial investment of a compound jaw crusher can be higher than that of a simpler jaw crusher |

Applications

- Mining

- Aggregate production

- Recycling

- बांधकाम

Blake Jaw Crusher

Blake jaw crusher is a jaw crusher with the movable jaw hinged at the top. It was invented by Eli Whitney Blake in 1858 and has become one of the most widely used jaw crushers for crushing a variety of materials, especially in the primary crushing stage.

Types

- Single Toggle Plate Blake Jaw Crusher: The active jaw is driven by a single toggle plate, which reduces friction and wear.

- Double Toggle Plate Blake Jaw Crusher: This type uses two toggle plates, which provides greater crushing force, making it suitable for more severe applications.

Advantages and disadvantages comparison

| Advantages | Disadvantages |

|---|---|

| High output and large feed volume | Large size and weight compared to other types of jaw crushers |

| Simple design and easy maintenance | Moving parts are prone to wear and require regular maintenance |

| High reduction ratio, suitable for large-scale crushing |

Applications

It is commonly used in the mining, quarrying and recycling industries to crush hard, abrasive materials such as ore, rock and concrete.