Электронная почта: [email protected]

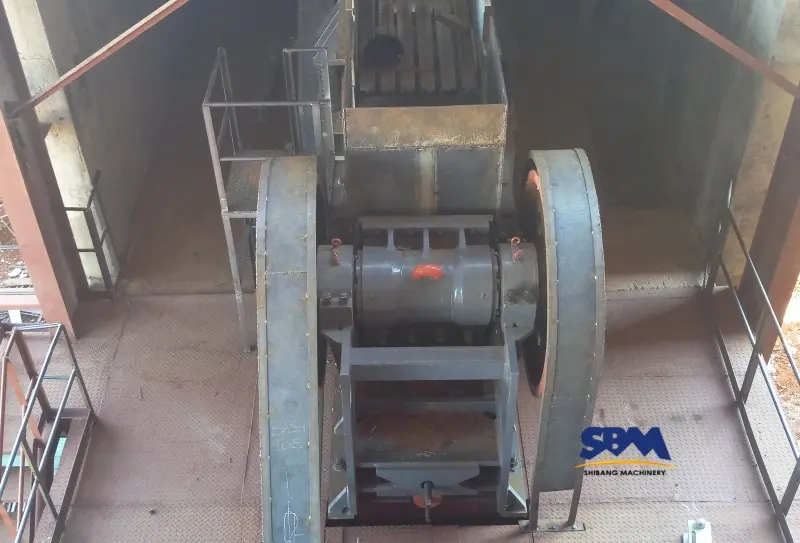

Дробление реки гравий с челюстями

Краеугольный камень современного строительства, River Gravel обеспечивает непревзойденную прочность и адаптивность для дорог, конкретный, и контроль эрозии. И все же это грубый, irregular nature demands machinery built to endure—enter jaw crushers. These heavy-duty workhorses now dominate global operations, pulverizing raw river stone into precision-grade aggregates. From Scandinavian quarries to disaster recovery sites in Iowa, this article unpacks how jaw crushers outperform alternatives, their engineering breakthroughs, and field-tested strategies to amplify productivity.

Why Jaw Crushers Excel in River Gravel Processing?

1. Durability Against Abrasive Materials

River gravel’s high silica content and irregular shapes demand equipment that can withstand wear. Щековые дробилки use manganese steel plates to resist abrasion while maintaining crushing efficiency. Their sturdy construction ensures longevity even in high-volume operations.

2. Flexibility in Output Sizing

Adjustable discharge settings allow operators to produce aggregates ranging from coarse gravel (50–100 mm) to finer grades (5–15 mm).

3. High Throughput with Low Energy Consumption

Advanced designs, such as hydraulic adjustment systems in Mobile Jaw Crushers, reduce downtime and optimize energy use. A case study in Australia’s Queensland mining region reported a throughput of 280 tons/hour with minimal power consumption.

Global Case Studies: Jaw Crushers in Action

Case 1: Sustainable Gravel Extraction in Scandinavia

In Norway, a quarry specializing in river gravel for road construction deployed the mobile jaw crusher. Its hybrid power system reduced diesel consumption by 30%, aligning with the region’s strict environmental regulations. The project achieved a crushing ratio of 6:1, transforming raw gravel into 40–70 mm aggregates for asphalt production.

Case 2: Disaster Recovery in the U.S. Midwest

After severe flooding damaged infrastructure in Iowa, contractors used tracked jaw crushers to process river debris. The machines’ mobility allowed rapid site transitions, while their 1,000 Икс 600 mm feed opening handled large boulders efficiently.

Technical Innovations Enhancing Performance

Hydraulic Overload Protection

Modern щековые дробилки integrate hydraulic systems to prevent damage from uncrushable objects.

Automated Gap Adjustment

Wedge-and-shim systems, like those in PE-1600 jaw crusher, enable operators to fine-tune discharge settings without halting operations. This feature is critical for maintaining consistent output in high-demand settings.

Maintenance Tips for Long-Term Efficiency

1. Regular Wear Plate Inspections

Replace manganese liners when wear exceeds 20% to prevent uneven crushing. The jaw crushers offer quick-release mechanisms for faster plate changes.

2. Lubrication and Dust Management

Use centralized grease systems to protect bearings from gravel dust. Pairing crushers with dust suppression units, as seen in Canadian quarries, extends component life by 15–20%.

3. Monitor Eccentric Shaft Speed

Maintain RPM within manufacturer guidelines (например, 160–320 RPM for mid-sized units) to balance productivity and energy use.

Future Trends: Smart Crushing Solutions

Emerging technologies like IoT-enabled sensors are transforming jaw crusher operations. A pilot project in Sweden’s LKAB Kiruna Mine uses real-time data analytics to predict liner wear and optimize feed rates, boosting annual output by 12%.

From Scandinavian quarries to North American disaster zones, jaw crushers prove indispensable in river gravel processing. Their blend of durability, adaptability, and technological innovation makes them a smart investment for aggregate producers worldwide. By adopting best practices in maintenance and leveraging advanced features, operators can achieve both economic and environmental sustainability.

Главный офис

WhatsApp:+8615225176731

Электронная почта: [email protected]

Адрес: Нет. 1688, Гаоке Ист Роуд, Новый район Пудун, Шанхай, Китай.

Веб-сайт: https://www.mill-sbm.com/

Содержание статьи

Недавние Посты

- Обработка золотой руды: Эффективность дробилки челюстиЭффективная обработка золотой руды зависит от точных операций дробления, где дробилки челюсти преобразуют прочные отложения в оптимизированный сырье. Узнайте, как точно настроить эти машины для пиковой продуктивности без ущерба для рабочих мест ...

- Дробление реки гравий с челюстямиКраеугольный камень современного строительства, River Gravel обеспечивает непревзойденную прочность и адаптивность для дорог, конкретный, и контроль эрозии. И все же это грубый, Нерегулярная природа требует техники, созданного для выдержания - введите дробилки.

- Как выбрать правильный размер дробилки для вашей отрасли?Выбор правильного размера дробилки - это не игра догадки - это наука, основанная на материальной динамике и операционном исчислении. Для отраслей от жесткой добычи до городского бетона переработка, даже…