อีเมล: [email protected]

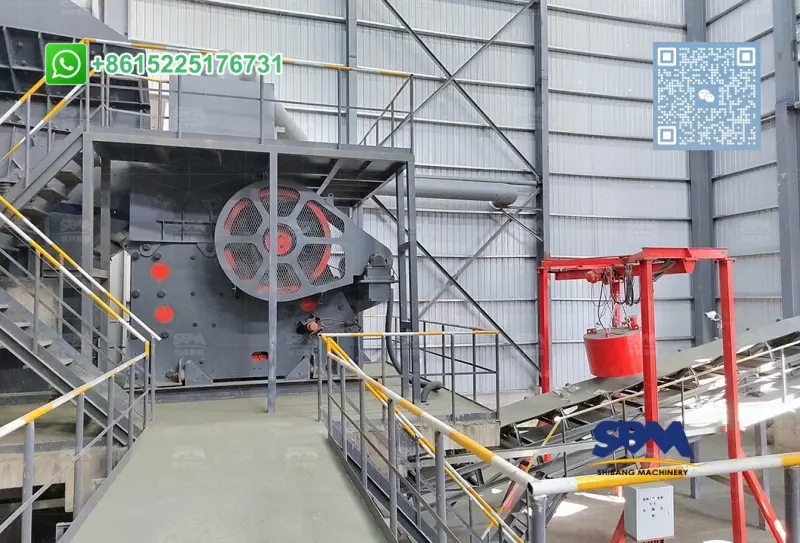

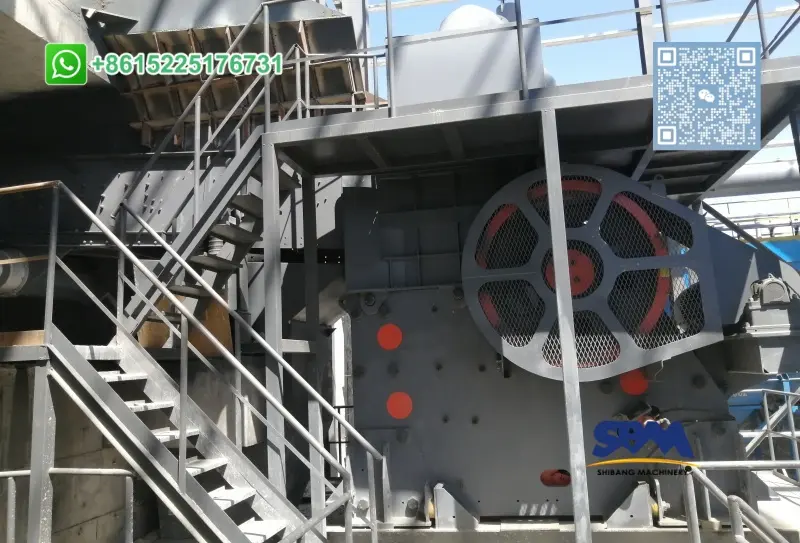

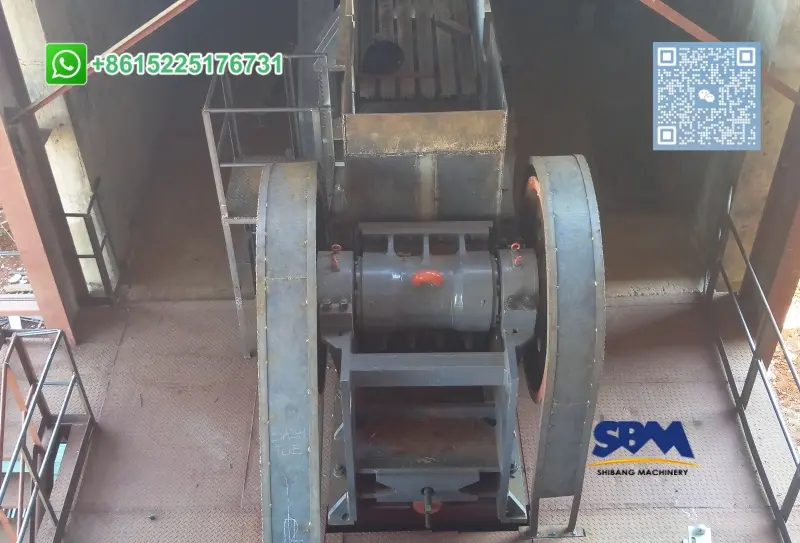

การปลดล็อคความสามารถในการบดกราม: จากหินแกรนิตแคนาดาไปจนถึงแร่เหล็กออสเตรเลีย

เมื่อเหมืองเหล็ก Lac Bloom ของ Quebec ต้องการให้ได้ 650 ตันต่อชั่วโมงอย่างสม่ำเสมอ, การตั้งค่า Jaw Crusher คงที่ของพวกเขากลายเป็นฮีโร่ - การประสบความสำเร็จ 93% เวลาทำงานผ่านการจัดการความจุอัจฉริยะ. This guide breaks downfixed jaw crusher capacity per hour realities across 15 global operations, with actionable tips to maximize your output.

The Capacity Equation: More Than Just Spec Sheets

Canadian Granite Crushing: The Numbers Game

PE600×900 model in Thunder Bay quarry:

| วัสดุ | Theoretical Capacity | Real-World Avg | Secret Boosters |

|---|---|---|---|

| หินแกรนิต | 60-160tph | 138tph | Laser-aligned CSS + optimized liner rotation |

| หินบะซอลต์ | 75-120tph | 102tph | Pre-screening >500mm chunks |

4 Capacity Killers (And How to Fix Them)

1. เดอะ “Hungry Jaw” Paradox

Overfeeding >500mm rocks reduces throughput by 40%.

สารละลาย:

Install grizzly screen with 300mm spacing.

2. Ghost blockage: the invisible killer of the crushing chamber

The material is unevenly accumulated in the crushing chamber, resulting in a 30-50% decrease in actual production capacity, which is common in flaky materials or ores with high clay content.

สารละลาย:

Step-type pre-screening: Install a double-layer vibrating screen (upper layer 300mm screen hole, lower layer 50mm) before the feed inlet. Chile’s Escondida copper mine reduced the blockage rate from 17% ถึง 3% through this solution.

Cavity modification: Use asymmetric toothed liner (upper tooth pitch 120mm, lower tooth pitch 80mm) to guide the material to flow to the discharge port.

Intelligent purge system: Install compressed air nozzles to automatically clear dead corner accumulation every 15 นาที (Australian FMG iron ore increased production capacity by 22%).

3. Bearing overheating: the silent capacity devourer

When the bearing temperature exceeds 85°C, the equipment automatically slows down, directly resulting in a 40% decrease in production capacity.

สารละลาย:

Lubrication upgrade: Use NLGI 2 grade polyurea-based grease, which has a temperature resistance 60°C higher than traditional lithium-based grease (data from Quebec granite mine in Canada).

Thermodynamic transformation: Add heat sink fins + forced air cooling system to the bearing seat, and the Turkish Boratas BCK series has a measured temperature reduction of 18°C.

Intelligent monitoring: Install wireless temperature sensors to automatically adjust the feed speed when the temperature difference is greater than 5°C.

4. Vibration imbalance: invisible production capacity loophole

A 0.2mm basic horizontal deviation will cause the vibration value to exceed the standard, forcing the equipment to operate at a reduced frequency, resulting in a fixed jaw crusher capacity loss of 25%.

สารละลาย:

Laser alignment system: Use laser alignment instrument to control the installation accuracy within ±0.05mm/m (the vibration value of the South African gold mine was reduced from 7mm/s to 2.3mm/s after application).

Dynamic counterweight technology: Install adjustable counterweight blocks on the flywheel to balance the eccentric shaft torque in real time (Improving production output stability by 19%).

Elastic foundation transformation: Use rubber-steel composite shock-absorbing base to absorb high-frequency vibration energy (the Vale case in Brazil reduced production capacity fluctuations by 37%).

2025 Tech Upgrades Changing the Game

- AI-Powered CSS Adjustment: Automatically adapts to material hardness (tested in Chilean copper mines)

- Smart Liners: RFID-tagged plates track wear in real-time—replace before failure

- Hybrid Power: Solar-diesel systems cut energy costs by 35% (Australian pilot data)

Capacity vs Cost: The 5-Year Math

| แบบอย่าง | Hourly Capacity | 2025 Price | Cost/Ton |

|---|---|---|---|

| PE400×600 | 16-65tph | $45k | $0.82 |

| PE600×900 | 60-160tph | $75k | $0.68 |

| PE1200×1500 | 400-800tph | $220k | $0.51 |

Compare models in 2025 price guide

Proven Maintenance Hacks for Steady Output

- The 400-Hour Rule: Rotate jaw plates every 400 operational hours (extends life by 2.3x)

- Vibration Checkups: Monthly laser alignment keeps hourly output within 5% of spec

- Lubrication Sweet Spot: 1.2kg EP-2 grease per bearing—overgreasing causes 38% failures

Future-Proof Your Setup

Modular Upgrades

Swap between granite/recycling modes in 4 ชั่วโมง (Norwegian pilot)

Carbon Accounting

New EU regulations reward 650+ tph operations with carbon credits

The Bottom Line: Capacity Is a Dance

As Brazil’s Vale engineers proved: matchingfixed jaw crusher capacity to your actual feed stock (not brochure numbers) can boost profits by 18%. Remember—your crusher’s true potential lies between its specs and your operational wisdom.

สำนักงานใหญ่

วอทส์แอพ:+8615225176731

อีเมล: [email protected]

ที่อยู่: เลขที่. 1688, ถนน Gaoke ตะวันออก, เขตผู่ตงใหม่, เซี่ยงไฮ้, จีน.

เว็บไซต์: https://www.mill-sbm.com/

เนื้อหาบทความ

โพสต์ล่าสุด

- Jaw Crusher for Limestone Processing: A Guide to EfficiencyAs limestone is widely used in construction and industry, its processing requires strong and durable jaw crusher to meet the needs of the industry. Among the many crushers, the jaw…

- Impact Crusher ด้วย 300 TPH สำหรับโครงการขนาดใหญ่When mining giants face mountains of iron ore or urban demolitions generate concrete avalanches, 300 TPH impact crusher emerges as material-processing titans. Beyond basic specs, we dissect how these industrial…

- เครื่องบดกระแทกราคาไม่แพง: ผู้เปลี่ยนเกมสำหรับธุรกิจก่อสร้างขนาดเล็กSmall construction companies often face budget constraints, yet need reliable equipment – an affordable impact crusher. This crusher can bridge the gap, providing efficient material processing without a huge capital…