อีเมล: [email protected]

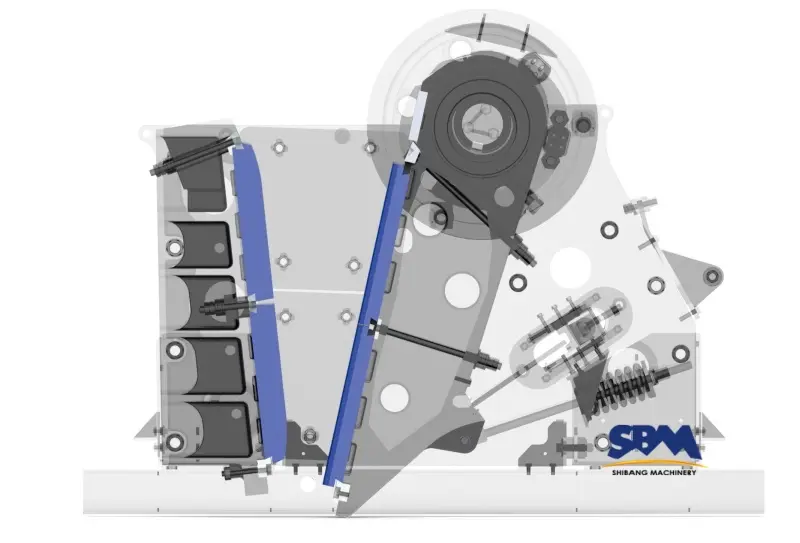

คู่มือทีละขั้นตอนเพื่อเปลี่ยน Liners Jaw Crusher: 8 ขั้นตอนสำคัญ

Properly replacing jaw crusher liner increases production efficiency by 40% และยืดอายุการใช้งานโดย 2-3 ปี. This comprehensive guide details professional techniques used insmall and large mining operations, ครอบคลุมโปรโตคอลความปลอดภัย, tool requirements, and precision alignment methods. Follow our 8-phase process to minimize downtime to under 4 hours per replacement.

Pre-Replacement Preparation

1. Safety Lockout Procedure

- Disconnect power supply and engage mechanical lockout

- Release hydraulic pressure (>5 minutes bleed time)

- Install fall protection for crusher pit access

2. Tool & Material Checklist

| Tool | Specification |

|---|---|

| Hydraulic Jack | 50-ton capacity |

| Torque Wrench | 300-800 N·m range |

| Liner Lifting Clamp | SWL 2,000kg |

Liner Replacement Process

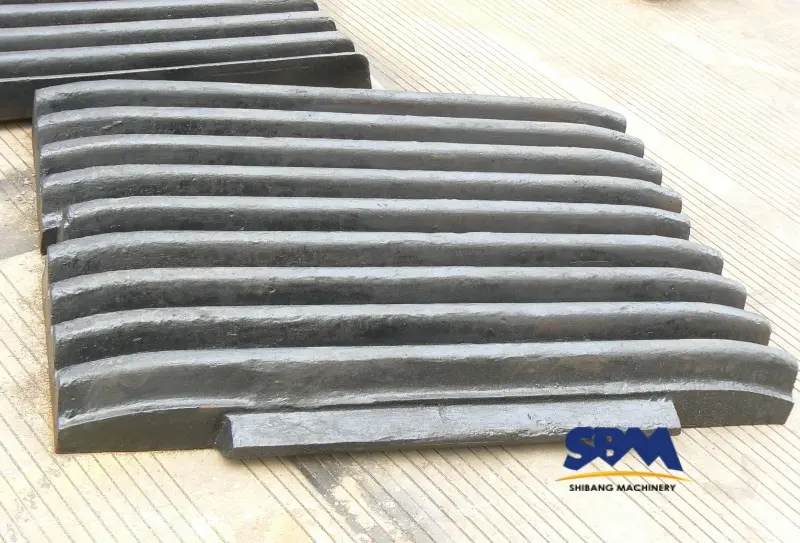

3. Remove Worn Liners

- Loosen wedge bolts in diagonal pattern (30% torque reduction)

- Useliner removal tools to break corrosion bond

- Extract upper wedges first, then side plates

4. Clean & Inspect Mounting Surface

- Remove debris with pneumatic chisel

- Check for cracks using dye penetrant

- Verify flatness (<0.5mm/m tolerance)

5. Install New Liners

| Component | Torque Spec | Sequence |

|---|---|---|

| Fixed Jaw | 650 N·m | Center-out |

| Movable Jaw | 720 N·m | Cross pattern |

6. Alignment Verification

Use laser alignment tools to ensure:

- Parallelism <0.2mm/m

- Vertical runout <0.3mm

- Propercrushing chamber geometry

Post-Installation Procedures

7. Run-in Process

- Start with 50% feed rate for 2 ชั่วโมง

- Monitor vibration (<4.5 mm/s RMS)

- Retorque after 8 hours operation

8. เอกสาร & Analysis

- Record liner serial numbers

- Measure initial wear pattern

- Updatepredictive maintenance schedule

Common Mistakes & Solutions

| Error | Consequence | Prevention |

|---|---|---|

| Improper torque | Liner movement | Use calibrated wrench |

| Missed alignment | Premature wear | Laser verification |

Quarry Productivity Improvement

A limestone operation reduced liner replacement time from 6.5 ถึง 3.8 hours by:

- Implementing our 8-step process

- Using optimized liner profiles

- Training crew on crusher kinematics

Essential Tools for Efficient Replacement

- Liner handler with vacuum lift

- Infrared thermal camera (check bearing temps)

- Digital thickness gauge (wear measurement)

Precision Saves Costs

Replacing jaw crusher liner requires understanding torque specifications, alignment tolerances, and proper run-in procedures. ดังนั้น, by integrating this guide with your preventive maintenance program andequipment documentation, operations typically achieve 18-24 month liner lifecycles even in abrasive conditions.

สำนักงานใหญ่

วอทส์แอพ:+8615225176731

อีเมล: [email protected]

ที่อยู่: เลขที่. 1688, ถนน Gaoke ตะวันออก, เขตผู่ตงใหม่, เซี่ยงไฮ้, จีน.

เว็บไซต์: https://www.mill-sbm.com/

เนื้อหาบทความ

โพสต์ล่าสุด

- How Jaw Crusher Design Enhances Operational Efficiency in Mining and ConstructionThe efficiency of a jaw crusher depends on its design. These design principles maximize production while minimizing energy consumption and downtime. ด้านล่าง, we analyze which key design features contribute to…

- ทำไม Jaw Crushers ถึงเป็นรากฐานของการขุดที่ไม่สั่นคลอน?ในโลกแห่งการขุดที่ขรุขระ, ในกรณีที่ประสิทธิภาพกำหนดผลกำไร, Jaw Crushers ยืนเป็นบรรทัดแรกของการป้องกันกับ RAW, แร่ที่ยังไม่ผ่านกระบวนการ. จากภูมิภาค Pilbara ที่อุดมด้วยเหล็กของออสเตรเลียไปจนถึงอาร์เจนตินา ...

- อุตสาหกรรมอะไรส่วนใหญ่ใช้เครื่องบดกราม? มุมมองระดับโลกแอปพลิเคชั่นของการบดกรามนั้นกว้างมากและอุตสาหกรรมจำนวนมากใช้มันเป็นหลัก. ในขณะที่การบดกรามอาจดูเหมือนช่างทำงานเชิงกลเรียบง่าย, ผลกระทบต่ออุตสาหกรรมสมัยใหม่คืออะไรก็ได้ ...