E-posta: satış@mill-sbm.com

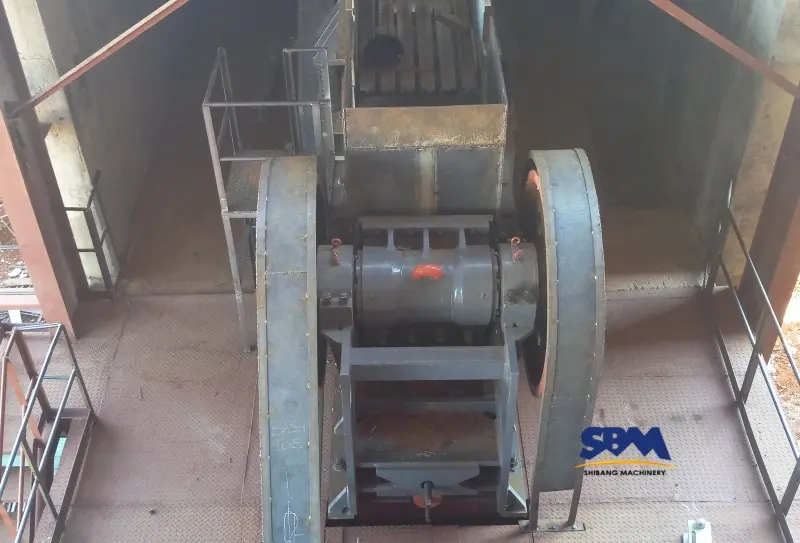

Installing a Jaw Crusher on Site: 2025 Field Guide for Construction Teams

When the Ontario Stone Co. team installed their new PE1200×1500 jaw crusher last month, they cut setup time from 3 days to 18 hours—saving $15,000 in labor costs. Here’s how modern construction site is revolutionizing crusher installation, blending old-school mechanical know-how with 2025’s smart tech.

bu 4 Golden Rules of Crusher Installation

Golden Rule 1: Precise foundation preparation – the foundation of installation success

Key operations:

- Concrete strength matching: The foundation concrete grade must be ≥C30, and the thickness must be 1.5 times the weight of the equipment (Örneğin, a 300-ton crusher requires a 450-ton foundation)

- Drainage system design: Set a 5° outward slope to prevent water accumulation from causing metal corrosion (in the case of Sudbury Nickel Mine in Canada, this reduced the problem of bolt rust by 80%)

- Anchor bolt pre-tightening technology: Use M42 high-strength anchor bolts, and increase the torque to 850N·m in three steps (the Chilean copper mine project uses a laser torque meter to achieve ±2% accuracy control)

- Failure case: İçinde 2023, a gold mine in South Africa had a foundation tilt of 0.5°, which caused the wear rate of the movable jaw assembly to accelerate by 300%, with an annual loss of $1.2 million.

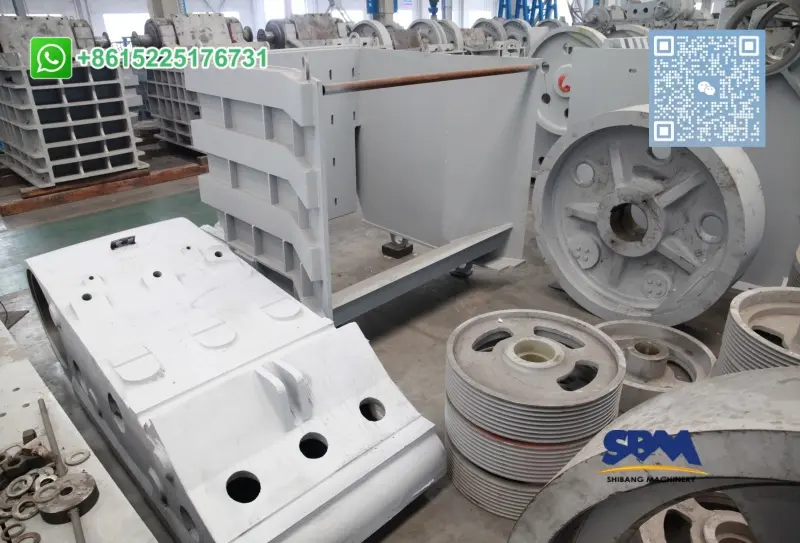

Golden Rule 2: Modular assembly process – a balance between efficiency and safety

Five-step assembly method:

- Chassis positioning: laser total station calibrates horizontality (error ≤ 0.1mm/m)

- Eccentric shaft installation: hydraulically press in after heating to 80°C to avoid cold installation deformation (refer to the Finnish factory standard)

- Moving jaw lifting: double-point balance beam technology to prevent 1.8-ton components from swinging (Norway Arctic Iron Mine uses drones to assist in lifting, increasing efficiency by 40%)

- Drive belt tensioning: ultrasonic dynamometer ensures tension value of 85-90N (Australian lithium mine project reduces belt slippage by 60% through this method)

- Lubrication system pre-activation: Before injecting high-temperature lithium-based grease, flush the pipeline with diesel circulation (impurity removal rate increased by 92% in the Congolese cobalt mine case)

Golden Rule 3: Intelligent calibration – from empiricism to data-driven

Three major digital tool applications:

- 3D laser scanning: Generate a three-dimensional model of the crushing chamber to ensure that the parallelism between the movable jaw and the fixed jaw is ≤0.2mm (after Vale of Brazil adopted this method, the liner life was extended to 2,200 saat)

- IoT vibration monitoring: Real-time warning of abnormal frequency during the installation phase (LKAB Iron Mine in Sweden used this technology to reduce the commissioning time from 48 hours to 6 saat)

- Thermal imaging pre-inspection: The alarm is triggered when the temperature difference of the bearing seat exceeds 5℃ (Oyu Tolgoi Copper and Gold Mine in Mongolia successfully prevented 3 major failures)

- Cost-effectiveness: Data from Chile’s Codelco shows that intelligent calibration reduces installation labor costs by 35%, but requires an initial investment of $50,000 in equipment purchase costs.

Golden Rule 4: Full-cycle Verification System – From Static Installation to Dynamic Optimization

Four-stage Verification Method:

- No-load test: Measure vibration value <4.5mm/s (ISO 10816-3 standard)

- Load increment: Load in steps of 25%-50%-75%-100%, monitor current fluctuation ≤10%

- Particle size sampling: Sampling every 30 minutes to verify the output particle size distribution (Indonesian nickel mine uses AI image analysis system to adjust CSS in real time)

- Energy efficiency audit: Compare kWh/ton index with manufacturer’s commitment value (a project in the Democratic Republic of Congo found transmission system defects through audit and claimed $280,000)

- Typical case: Australian FMG Group found foundation settlement problems through full-cycle verification during the installation acceptance of Pilbara iron ore, avoiding potential losses of $4.5 million.

Extended points: Economic decision support

Selection of new and old equipment: Although the installation cost of second-hand equipment is 15% lower, the calibration time is increased by 50% (see [Cost comparison analysis of new and old jaw crushers] for details)

Maintenance pre-planning: Reserving sensor interfaces during the installation phase can increase [maintenance efficiency by 70%] in the later stage

The above rules integrate mechanical engineering, material science and digital technology. It is recommended to refer to [Jaw Crusher Selection Guide] Ve [Capacity Optimization Manual] to formulate implementation plans based on specific working conditions.

Smart Tools Changing the Game

Laser Alignment Kits

Reduces jaw plate gap errors by 92% compared to manual measurement

IoT Vibration Sensors

Detect foundation issues in real-time (used in Norway’s Arctic mines)

Cost-Saving Pro Tips

- Rent vs Buy: For projects under 6 aylar, used mobile units save 40% on transport

- Pre-Assembled Kits: Yeni 2025 models arrive 70% pre-built

- Hybrid Power: Solar-diesel combos cut energy costs by 35%

The Canadian Success Blueprint

Ontario 500T/H Quarry Installation

| Step | Time | Tech Used |

|---|---|---|

| Foundation Pour | 2 days | Fast-cure concrete (+accelerator) |

| Mechanical Assembly | 6 saat | Laser-guided crane systems |

| Test Run | 1.5 saat | Vibration analysis software |

Result: Achieved target 450tph capacity within 2% tolerance

When Things Go South: Quick Fixes

Vibration Overload

Symptom: 5mm frame movement during first run

Düzeltmek: Re-torque anchor bolts + add rubber isolators

Belt Slip

Symptom: 15% power loss

Düzeltmek: Adjust tension to 85-90N using ultrasonic gauge

Future-Proofing Your Setup

- AI Optimization: Yeni2025 C6X models auto-adjust based on material hardness

- Modular Design: Swap from granite to recycling mode in 4 saat

- Drone Surveys: Pre-site analysis reduces foundation errors by 60%

Expert Verdict: Installation = 50% of Performance

As Toronto-based engineer Mark Wu notes: “A $2M crusher installed poorly performs like a $800k unit. But a mid-rangeçene kırıcı with precision setup can outperform premium models.”

Genel Müdürlük

Naber:+8615225176731

E-posta: satış@mill-sbm.com

Adres: HAYIR. 1688, Gaoke Doğu Yolu, Pudong yeni bölge, Şanghay, Çin.

İnternet sitesi: https://www.mill-sbm.com/

Makale İçeriği

yakın zamanda Gönderilenler

- Gold Ore Processing: Jaw Crusher EfficiencyEffective gold ore processing hinges on precise crushing operations, where jaw crushers convert rugged deposits into optimized feedstock. Discover how to fine-tune these machines for peak productivity without compromising worksite…

- Çene kırıcılarla ezici nehir çakılModern inşaatın temel taşı, River Gravel, yollar için eşsiz tokluk ve uyarlanabilirlik sağlar, beton, ve erozyon kontrolü. Yine de sağlam, Düzensiz doğa, katlanmak için inşa edilen makinelerin gerektirdiği - çene kırıcılara girin.…

- Endüstriniz için doğru çene kırıcı boyutunu nasıl seçersiniz??Doğru çene kırıcı boyutunu seçmek bir tahmin oyunu değildir - malzeme dinamikleri ve operasyonel hesaplardan kaynaklanan bir bilimdir. Sabit kaya madenciliğinden kentsel beton geri dönüşümüne kadar sektörler için, Hatta bir…