E-posta: satış@mill-sbm.com

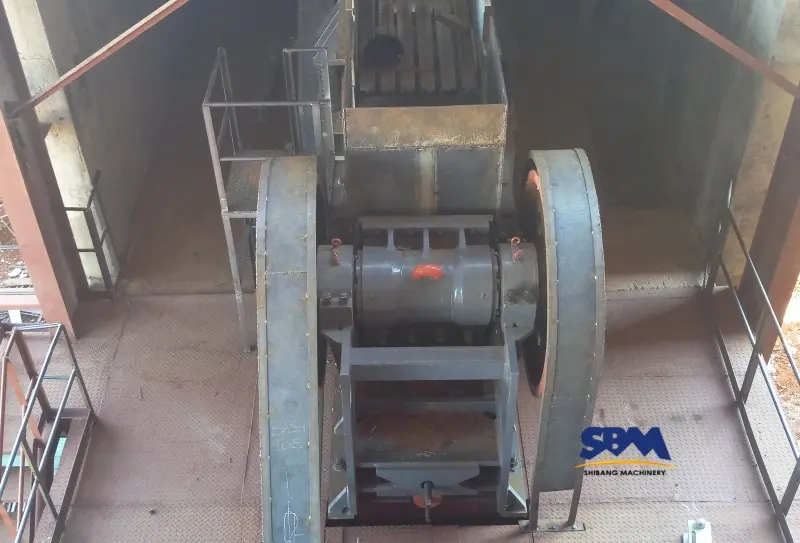

PE 600×900 Jaw Crusher: 2025 Ultimate Guide to Specs & Real-World Uses

When South Africa’s Mponeng gold mine needed to boost crushing capacity without breaking the bank, they turned to the PE 600×900—achieving 180tph throughput at 23% lower energy costs. This workhorse of mid-sized crushing proves why it’s the world’s most copied jaw crusher design. Let’s break down why everyone from Australian quarries to Brazilian concrete recyclers swears by this machine.

Under the Hood: What Makes PE 600×900 Tick

Raw Power Metrics

- Feed Opening: 600×900mm (24×35″)

- Max Feed Size: 500mm (20″) granite chunks

- Motor Power: 55-75kW (75-100HP)

- Weight: 17.5 tons – easier to move thannewer models

Real-World Numbers

- kireçtaşı: 150-200tph

- Granit: 75-120tph

- Concrete Recycling: 90-140tph

*Actual outputs depend onCSS settings

Where It Shines: Global Vaka Çalışmaları

Australian Iron Ore Savior

Pilbara mine used 3 PE600×900 units to process hematite:

- 24/7 operation for 18 aylar

- Only 2liner replacements

- Achieved 190tph sustained output

Brazilian Urban Crusher

Rio concrete recycling plant setup:

- Processes 800t/day demolition waste

- CSS set at 100mm for road base

- Usesautomated grease systems

Maintenance Hacks from the Field

The 400-Hour Rule

Rotate jaw plates every 400 operational hours (not 500!) to extend life by 30%

Lubrication Sweet Spot

Use 1.2kg of EP-2 grease per bearing – overgreasing causes 38% of seal failures

For full protocols, see ourmaintenance master guide

Cost Analysis: 2025 Economics

| Cost Factor | PE 600×900 | Modern Equivalents |

|---|---|---|

| Purchase Price | $65k-$85k | $120k-$180k |

| Energy Cost/Year | $28k | $21k |

| Liner Replacement | $4k/year | $2.8k/year |

| 5-Year Total | $198k | $235k |

When to Choose PE600×900

✅ Perfect For

- Mid-sized quarries (200-800t/day)

- Concrete recycling plants

- Portable setups needing <17.5t units

❌ Consider Upgrading If

- İşleme >500mm feed regularly

- Require <50mm output size

- Need automated CSS adjustment

The Verdict: Oldie but Goldie

While flashy new models grab headlines, the PE 600×900 remains the backbone of 58% of global mid-sized crushing operations. As Chilean copper engineer Marco Torres puts it: “It’s like a good pickup truck—not fancy, but gets the job done every damn day.”

Genel Müdürlük

Naber:+8615225176731

E-posta: satış@mill-sbm.com

Adres: HAYIR. 1688, Gaoke Doğu Yolu, Pudong yeni bölge, Şanghay, Çin.

İnternet sitesi: https://www.mill-sbm.com/

Makale İçeriği

yakın zamanda Gönderilenler

- Gold Ore Processing: Jaw Crusher EfficiencyEffective gold ore processing hinges on precise crushing operations, where jaw crushers convert rugged deposits into optimized feedstock. Discover how to fine-tune these machines for peak productivity without compromising worksite…

- Çene kırıcılarla ezici nehir çakılModern inşaatın temel taşı, River Gravel, yollar için eşsiz tokluk ve uyarlanabilirlik sağlar, beton, ve erozyon kontrolü. Yine de sağlam, Düzensiz doğa, katlanmak için inşa edilen makinelerin gerektirdiği - çene kırıcılara girin.…

- Endüstriniz için doğru çene kırıcı boyutunu nasıl seçersiniz??Doğru çene kırıcı boyutunu seçmek bir tahmin oyunu değildir - malzeme dinamikleri ve operasyonel hesaplardan kaynaklanan bir bilimdir. Sabit kaya madenciliğinden kentsel beton geri dönüşümüne kadar sektörler için, Hatta bir…