E-posta: satış@mill-sbm.com

Kum Çekirdek Yapma Makinesi: Parça İmalatı, Toplantı, ve Makine Çalışması

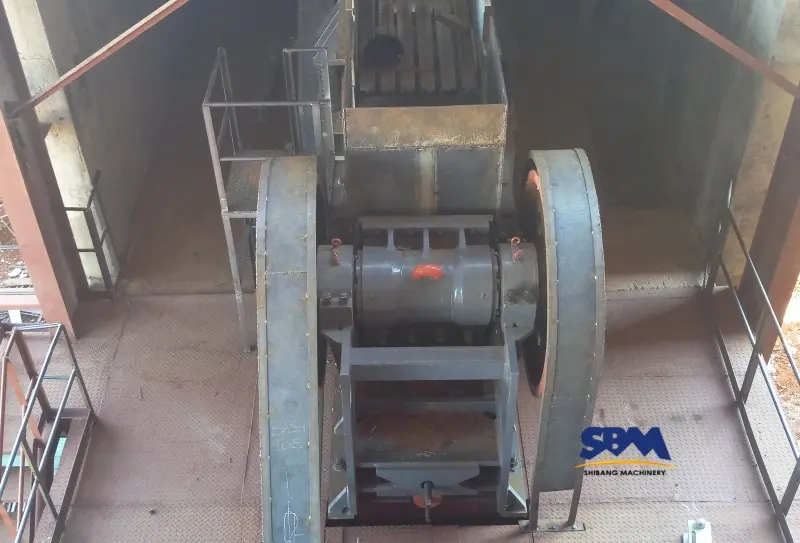

Sand core making machine plays a vital role in various industries, enabling the production of intricate sand cores used in casting processes. This article will delve into the process of fabricating and assembling the different components of a sand core making machine, as well as the subsequent machine operation and debugging.

Parça İmalatı

The production of a kum yapma makinesi involves the creation of several crucial components. These components include the following:

- A) Frame and Base: The frame and base provide structural support to the machine. They are fabricated using sturdy materials such as steel or iron, ensuring stability during operation.

- b) Konveyör Sistemi: The conveyor system transports the sand and other materials within the machine. It consists of belts, rollers, and pulleys, fabricated to withstand the heavy loads and continuous operation.

- c) Sand Hopper: The sand hopper stores the raw material, allowing a steady supply of sand for the core making process. It is fabricated with durable materials and designed for easy loading and unloading.

- D) Mixing Mechanism: The mixing mechanism blends sand with binders and other additives to create a homogeneous mixture. It comprises motors, gears, and mixing blades, fabricated for efficient mixing and uniform distribution.

Toplantı

Once the individual components are fabricated, the assembly process begins. The following steps outline the assembly of a sand core making machine:

- A) Framework Assembly: The frame and base are assembled, ensuring proper alignment and secure connections. Precision measurements and welding techniques are employed to achieve a sturdy structure.

- b) Integration of Components: The conveyor system, sand hopper, mixing mechanism, and other relevant parts are integrated into the machine. Careful attention is given to proper alignment and secure fastening to ensure smooth operation.

- c) Electrical and Control System Integration: Electrical wiring, motors, sensors, and control panels are integrated to enable automated operation and precise control of the machine’s functions. Thorough testing and adherence to safety standards are crucial during this stage.

Machine Operation and Debugging

After assembly, the sand core making machine undergoes a series of operation and debugging procedures to ensure optimal performance. This includes:

- A) Power-Up and Initial Testing: The machine is connected to a power source, and initial tests are conducted to verify the functionality of individual components and the overall system.

- b) Calibration and Adjustment: Parameters such as sand-to-binder ratio, mixing speed, and conveyor speed are adjusted based on specific requirements. Calibration ensures consistent and accurate core production.

- c) Trial Runs and Quality Assessment: The machine is operated using sample materials to produce sand cores. The cores are inspected for dimensional accuracy, surface finish, and structural integrity, ensuring that the machine meets desired quality standards.

The process of creating a sand core making machine involves meticulous fabrication of various components, their assembly into a functional unit, and subsequent operation and debugging. The successful development of a well-designed and efficiently functioning sand core making machine is instrumental in enhancing the casting processes and productivity across industries.

Genel Müdürlük

Naber:+8615225176731

E-posta: satış@mill-sbm.com

Adres: HAYIR. 1688, Gaoke Doğu Yolu, Pudong yeni bölge, Şanghay, Çin.

İnternet sitesi: https://www.mill-sbm.com/

Makale İçeriği

yakın zamanda Gönderilenler

- Gold Ore Processing: Jaw Crusher EfficiencyEffective gold ore processing hinges on precise crushing operations, where jaw crushers convert rugged deposits into optimized feedstock. Discover how to fine-tune these machines for peak productivity without compromising worksite…

- Çene kırıcılarla ezici nehir çakılModern inşaatın temel taşı, River Gravel, yollar için eşsiz tokluk ve uyarlanabilirlik sağlar, beton, ve erozyon kontrolü. Yine de sağlam, Düzensiz doğa, katlanmak için inşa edilen makinelerin gerektirdiği - çene kırıcılara girin.…

- Endüstriniz için doğru çene kırıcı boyutunu nasıl seçersiniz??Doğru çene kırıcı boyutunu seçmek bir tahmin oyunu değildir - malzeme dinamikleri ve operasyonel hesaplardan kaynaklanan bir bilimdir. Sabit kaya madenciliğinden kentsel beton geri dönüşümüne kadar sektörler için, Hatta bir…