E-posta: satış@mill-sbm.com

Step-by-Step Guide to Replacing Jaw Crusher Liners: 8 Key Phases

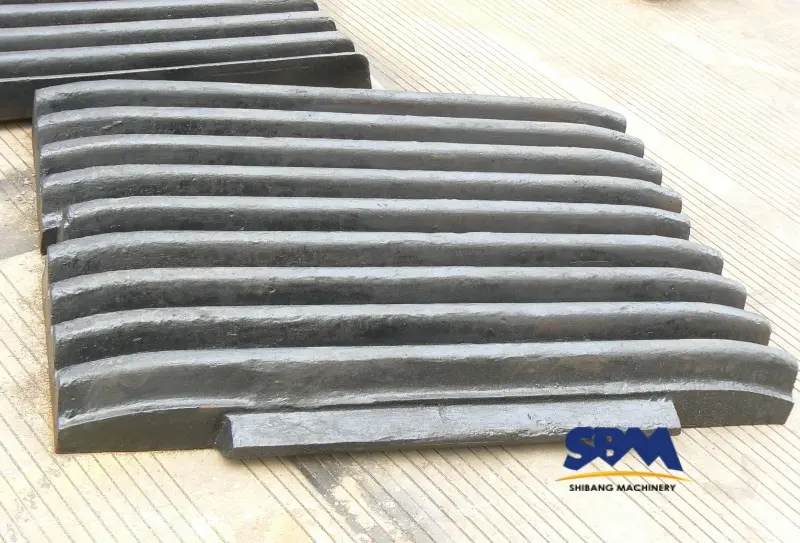

Properly replacing jaw crusher liner increases production efficiency by 40% and extends component life by 2-3 yıl. This comprehensive guide details professional techniques used insmall and large mining operations, covering safety protocols, tool requirements, and precision alignment methods. Follow our 8-phase process to minimize downtime to under 4 hours per replacement.

Pre-Replacement Preparation

1. Safety Lockout Procedure

- Disconnect power supply and engage mechanical lockout

- Release hydraulic pressure (>5 minutes bleed time)

- Install fall protection for crusher pit access

2. Tool & Material Checklist

| Tool | Specification |

|---|---|

| Hydraulic Jack | 50-ton capacity |

| Torque Wrench | 300-800 N · m Aralık |

| Liner Lifting Clamp | SWL 2,000kg |

Liner Replacement Process

3. Remove Worn Liners

- Loosen wedge bolts in diagonal pattern (30% torque reduction)

- Useliner removal tools to break corrosion bond

- Extract upper wedges first, then side plates

4. Clean & Inspect Mounting Surface

- Remove debris with pneumatic chisel

- Check for cracks using dye penetrant

- Verify flatness (<0.5mm/m tolerance)

5. Install New Liners

| Component | Torque Spec | Sequence |

|---|---|---|

| Fixed Jaw | 650 N·m | Center-out |

| Movable Jaw | 720 N·m | Cross pattern |

6. Alignment Verification

Use laser alignment tools to ensure:

- Parallelism <0.2mm/m

- Vertical runout <0.3mm

- Propercrushing chamber geometry

Post-Installation Procedures

7. Run-in Process

- Start with 50% feed rate for 2 saat

- Monitor vibration (<4.5 mm/s RMS)

- Retorque after 8 hours operation

8. Belgeler & Analysis

- Record liner serial numbers

- Measure initial wear pattern

- Updatepredictive maintenance schedule

Common Mistakes & Çözümler

| Error | Consequence | Önleme |

|---|---|---|

| Improper torque | Liner movement | Use calibrated wrench |

| Missed alignment | Premature wear | Laser verification |

Quarry Productivity Improvement

A limestone operation reduced liner replacement time from 6.5 ile 3.8 hours by:

- Implementing our 8-step process

- Using optimized liner profiles

- Training crew on crusher kinematics

Essential Tools for Efficient Replacement

- Liner handler with vacuum lift

- Infrared thermal camera (check bearing temps)

- Digital thickness gauge (wear measurement)

Precision Saves Costs

Replacing jaw crusher liner requires understanding torque specifications, alignment tolerances, and proper run-in procedures. Öyleyse, by integrating this guide with your preventive maintenance program andequipment documentation, operations typically achieve 18-24 month liner lifecycles even in abrasive conditions.

Genel Müdürlük

Naber:+8615225176731

E-posta: satış@mill-sbm.com

Adres: HAYIR. 1688, Gaoke Doğu Yolu, Pudong yeni bölge, Şanghay, Çin.

İnternet sitesi: https://www.mill-sbm.com/

Makale İçeriği

yakın zamanda Gönderilenler

- Jaw Crusher for Limestone Processing: A Guide to EfficiencyAs limestone is widely used in construction and industry, its processing requires strong and durable jaw crusher to meet the needs of the industry. Among the many crushers, the jaw…

- Impact crusher with 300 TPH for large projectsWhen mining giants face mountains of iron ore or urban demolitions generate concrete avalanches, 300 TPH impact crusher emerges as material-processing titans. Beyond basic specs, we dissect how these industrial…

- Uygun fiyatlı darbe kırıcı: Küçük inşaat işletmeleri için bir oyun değiştiriciKüçük inşaat şirketleri genellikle bütçe kısıtlamalarıyla karşı karşıyadır, Yine de güvenilir ekipmana ihtiyacım var – Uygun fiyatlı bir darbe kırıcı. Bu kırıcı boşluğu kapatabilir, Büyük bir sermaye olmadan verimli malzeme işleme sağlamak…