E-posta: satış@mill-sbm.com

Optimal ezme verimliliği için darbe kırıcıların temel bileşenlerini anlamak

This guide explores the key components of impact crushers, their functions, and real-world applications in global industries.

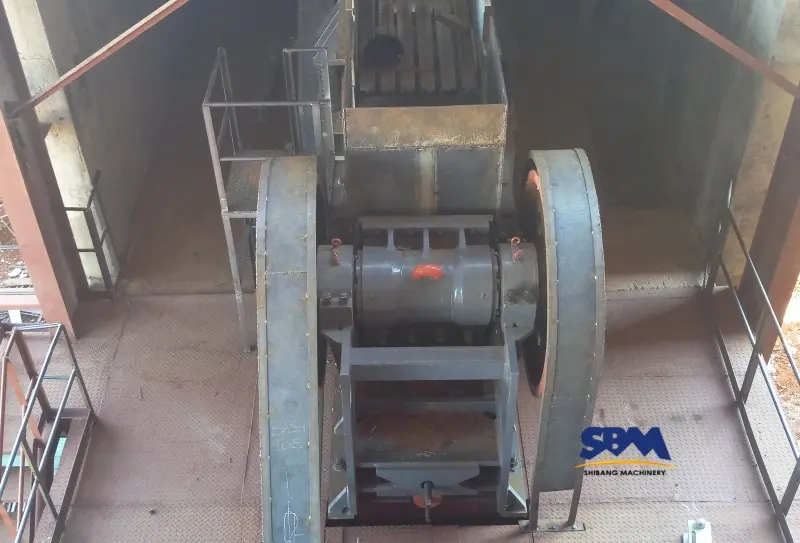

Key Components of Impact Crushers

1. Rotor Assembly: The Heart of Crushing Efficiency

The rotor is the central rotating element that generates the force needed to crush materials. Equipped with hammers or blow bars, it spins at high speeds to strike incoming feed. Örneğin, the VSI6X kum yapma makinesi (producing 100–583 tons/hour) uses a heavy-duty rotor with wear-resistant alloys, ideal for processing granite in UK quarries.

Key Features:

- Blow Bars: Replaceable metal bars attached to the rotor.

- Rotor Discs: Secure blow bars and balance rotation.

2. Impact Aprons and Grates: Shaping the Final Product

Impact aprons (or breaker plates) line the crushing chamber, redirecting materials for secondary collisions. Adjustable grates control output size, ensuring uniformity. A German recycling plant using a VSI kırıcı (60–520 tons/hour) reported a 30% improvement in slag recycling efficiency by optimizing apron gaps.

3. Drive System: Powering Performance

The motor and belt/pulley system drive the rotor. High-torque motors, like the 315 kW unit in the tertiary crusher, enable consistent crushing of hard rocks in U.S. mining operations.

4. Housing and Frame: Durability Under Pressure

The crusher’s outer structure withstands extreme forces. Robust steel frames, such as those in primary impact crushers, ensure stability during high-volume operations6.

Global Applications of Impact Crushers

Vaka çalışması 1: Fixed Crusher for Slag Recycling in Germany

A steel plant in Dortmund uses a PFW darbeli kırıcı to process 400 tons of slag daily. Adjustable aprons and tungsten carbide blow bars reduce wear, achieving 95% material reuse.

Vaka çalışması 2: How to Crush Rocks Efficiently in Australia

A Queensland quarry employs an CI5X Impact crusher with a multi-functional rotor to produce road base aggregates. Its 585-ton/hour capacity cuts operational costs by 20%.

Maintenance Tips for Longevity

- Inspect Blow Bars Regularly: Replace worn bars to maintain crushing efficiency.

- Lubricate Bearings: Prevent overheating in the drive system.

- Adjust Apron Gaps: Optimize output size for specific materials like limestone or recycled concrete.

Çözüm: Optimizing Impact Crusher Performance

From the rotor to the housing, key components of impact crushers play a critical role in material processing. Whether for slag recycling veya rock crushing, selecting the right impact crusher model—such as PF, PFW, CI5X, HERKES, VSI5X or VSI6X—ensures high efficiency and cost savings. For tailored solutions, explore our guides on kırma verimliliği Ve how to crush rocks effectively.

Genel Müdürlük

Naber:+8615225176731

E-posta: satış@mill-sbm.com

Adres: HAYIR. 1688, Gaoke Doğu Yolu, Pudong yeni bölge, Şanghay, Çin.

İnternet sitesi: https://www.mill-sbm.com/

Makale İçeriği

yakın zamanda Gönderilenler

- Gold Ore Processing: Jaw Crusher EfficiencyEffective gold ore processing hinges on precise crushing operations, where jaw crushers convert rugged deposits into optimized feedstock. Discover how to fine-tune these machines for peak productivity without compromising worksite…

- Çene kırıcılarla ezici nehir çakılModern inşaatın temel taşı, River Gravel, yollar için eşsiz tokluk ve uyarlanabilirlik sağlar, beton, ve erozyon kontrolü. Yine de sağlam, Düzensiz doğa, katlanmak için inşa edilen makinelerin gerektirdiği - çene kırıcılara girin.…

- Endüstriniz için doğru çene kırıcı boyutunu nasıl seçersiniz??Doğru çene kırıcı boyutunu seçmek bir tahmin oyunu değildir - malzeme dinamikleri ve operasyonel hesaplardan kaynaklanan bir bilimdir. Sabit kaya madenciliğinden kentsel beton geri dönüşümüne kadar sektörler için, Hatta bir…