E-mail: [email protected]

Bán thiết bị gia công nghiền và mài nóng cho thạch anh

Thạch anh là một khoáng chất đặc biệt hữu ích trong nhiều ngành công nghiệp bao gồm cả thủy tinh, gốm sứ và điện tử. Chọn thiết bị xử lý nghiền và nghiền phù hợp cho thạch anh là một bước quan trọng trong sản xuất nhiều mặt hàng.

máy nghiền hàm, máy nghiền tác động, máy nghiền côn, hammer mills, and ball mills are common pieces of quartz crushing and grinding equipment. The role of máy nghiền hàm is to break large rocks into smaller debris, while impact crushers and cone crushers can be secondary crushing. For grinding we often use hammer mills and ball mills.

The sand mill is also popular with customers to get fine size and high quality sand in the sand production process because quartz crusher plants can crush quartz particles from 10mm to 40mm.

Sand and quartz stone are ground together to create quartz sand. The jaw crusher serves as the primary crushing device in the quartz sand production line, followed by the impact crusher for fine grinding and the sand maker (vsi5x crusher) for producing sand and stone. We use vibrating screens as screening equipment to screen suitable sand.

Quartz crusher usually crush thạch anh into particles from 10mm to 40mm for construction such as highways, highways and railways. Sometimes, we often use quartz crushers in gold mining projects to crush granite, đá hoa, thạch anh, vân vân. in gold ore.

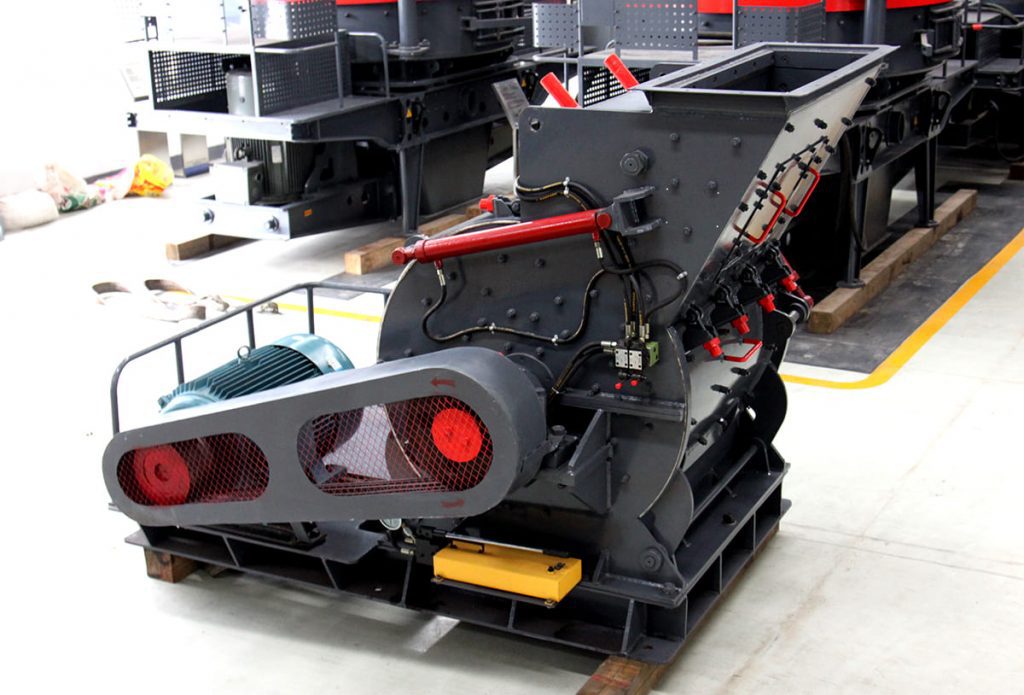

Crushing Processing Equipment For Quartz

There are several types of machines in the quartz sand production line. The main machine is quartz crushing equipment.

Jaw crusher for quartz. The function of jaw crusher is to crush materials and grade granite, đá hoa, gold ore and quartz. Jaw crusher has the following advantages: simple structure and reliable operation, easy maintenance and low cost of operation.

Quartz Sand Impact Crusher: An impact crusher for fine crushing of quartz used in quartz crushing complex. The most obvious advantage is the excellent function overhaul. Quartz impact crusher is suitable for producing high quality crusher for highway, energy and building materials industries.

VSI crusher for quartz sand: Another name for a máy nghiền VSI is a sand making machine. The action process of VSI crusher is fine crushing and coarse grinding of gravel, thạch anh, đá bazan, sandstone, silicon carbide and sintered bauxite.

The quartz raw material enters the jaw crusher for primary crushing, and the crushed material enters the cone crusher or impact crusher through the belt conveyor for secondary crushing. After secondary crushing, the quartz stone passes through the vibrating screen to separate the required particle size.

Grinding Processing Equipment For Quartz

In the sand making process, usually the sand mill is also popular with customers, in order to get fine size and high quality sand.

Quartz Sand Hammer Mill: The hammer mill is mainly used to grind coarse powder and produce fine sand. And its output size of 0-3mm can reach more than 90%.

The quartz is crushed into small particles before being ground in a ball mill or hammer mill during the grinding process. A classifier separates the ground material, and the coarse particles are returned to the mill for further grinding.

In Conclusion

It is critical to select the right crushing and grinding processing equipment for the unique properties of the quartz being processed, such as hardness, kích cỡ, and shape. Proper equipment selection can boost efficiency and reduce energy usage, leading to cost savings and enhanced output.

trụ sở văn phòng

Whatsapp:+8615225176731

E-mail: [email protected]

Địa chỉ: KHÔNG. 1688, Đường Đông Gaoke, quận mới Phố Đông, Thượng Hải, Trung Quốc.

Trang mạng: https://www.mill-sbm.com/

Nội dung bài viết

Bài viết gần đây

- Step-by-Step Guide to Replacing Jaw Crusher Liners: 8 Key Phases

- How to Lubricate Jaw Crusher Bearings: Expert Guide to Prevent Failure

- Common Jaw Crusher Problems and Solutions: Your Complete Maintenance Checklist

- Jaw Plate Selection Guide: Optimize Performance for Your Crushing Operation

- Jaw Crusher Capacity and Output Size Guide for Quarrying Operations

- How to Choose the Right Jaw Crusher for Mining Operations: A Comprehensive Guide