E-mail: [email protected]

Máy nghiền hàm hoạt động như thế nào?

Before we understand “how does jaw crusher work?”, we need to understand what is a jaw crusher and the basic components of a jaw crusher. Then let’s take a look at the types of jaw breakers.

What is a jaw crusher?

Jaw crusher is a commonly used mining machinery and equipment, which crushes larger stones or ores through the mutual extrusion of fixed jaws and movable jaws. Its main function is to reduce the size of mined ore for processing or transportation. máy nghiền hàm (for sale) are used to great effect in mines and quarries as well as in recycling processes where the reduction of bulky materials is required. The crushing equipment is widely used in mining, metallurgy, vật liệu xây dựng, construction and other industries.

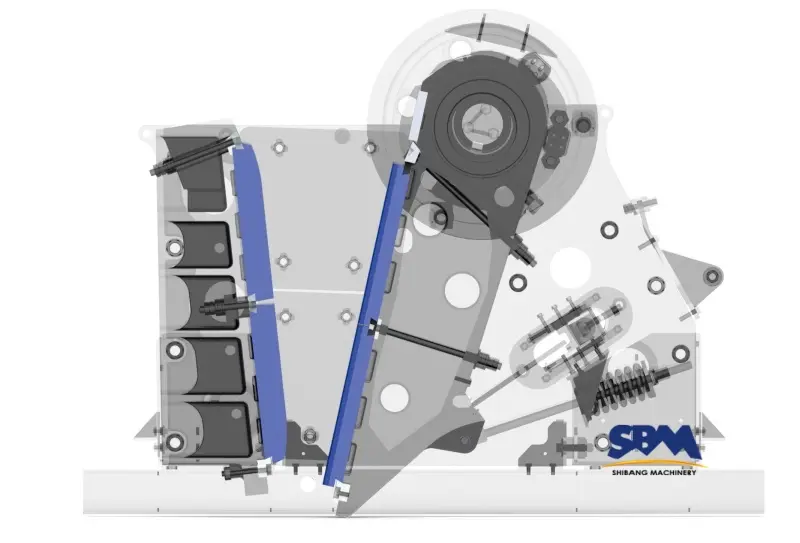

Basic components of jaw crusher

- Fixed jaw and movable jaw

- Jaw liner

- Eccentric shaft

- Drive pulley

- Bracket

How does a jaw crusher work?

After having a basic understanding of the jaw crusher machine, let’s see how the jaw crusher works.

Feeding stage

The ore or rock to be crushed enters the crushing chamber (the volume or cavity between the two jaws) through the vibrating grid feeder. The power provided by the motor rotates the eccentric shaft. As the eccentric shaft rotates, the movable jaw reciprocates.

Crushing stage

At this time, the ore or rock enters the crushing chamber. The movable jaw begins to exert pressure on the rock in the crushing chamber. The ore is squeezed into smaller pieces and gradually flows down to the lower discharge port.

Discharging stage

After the ore is crushed to a set size, it is discharged from the crushing chamber through the lower discharge port. The size of the final product can be pre-set.

How to adjust the discharge size?

Use wedges or hydraulic systems to adjust the gap between the two jaws.

SBM jaw crushers include safety features such as toggle plates. It protects the crusher from overload or uncrushable materials. Jaw crushers are heavy machines, so regular maintenance ensures that the jaw crusher operates efficiently. Maintenance operations include lubricating bearings, checking jaw wear, and tightening or replacing any loose or worn parts.

Types of Jaw Crusher

Máy nghiền hàm PE

Là máy nghiền sơ cấp cổ điển với hiệu suất ổn định, Máy nghiền hàm PE được sử dụng rộng rãi để nghiền quặng kim loại và phi kim loại cũng như cốt liệu xây dựng hoặc làm cát nhân tạo.

Máy nghiền hàm PEW

Máy nghiền hàm PEW là loại máy nghiền mới được phát triển bởi SBM, nhà sản xuất máy nghiền hàm, sau khi phát hành máy nghiền hàm truyền thống. Bên cạnh đó, this jaw crusher is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of vast customers.

Máy nghiền hàm C6X

Tất cả các chỉ số của Máy nghiền hàm C6X về kết cấu và hiệu quả sản xuất đều thể hiện công nghệ hiện đại tiên tiến. Vì thế, SBM’s C6X Jaw Crusher can solve such problems of the existing universal jaw crushers as low production efficiency, lắp đặt và bảo trì khó khăn. Hiện tại, Máy nghiền hàm C6X là máy nghiền thô lý tưởng tại thị trường trong nước.

trụ sở văn phòng

Whatsapp:+8615225176731

E-mail: [email protected]

Địa chỉ: KHÔNG. 1688, Đường Đông Gaoke, quận mới Phố Đông, Thượng Hải, Trung Quốc.

Trang mạng: https://www.mill-sbm.com/

Nội dung bài viết

Bài viết gần đây

- Beyond Rocks: The Surprising Materials Jaw Crushers Can ProcessWhile “rock crusher” might conjure images of granite mountains, new jaw crushers process materials that would surprise even seasoned engineers. Let’s examine their true capabilities through global operational data and…

- How Jaw Crusher Design Enhances Operational Efficiency in Mining and ConstructionThe efficiency of a jaw crusher depends on its design. These design principles maximize production while minimizing energy consumption and downtime. Dưới, we analyze which key design features contribute to…

- Why Jaw Crushers Are the Unshakable Foundation of Mining?In the rugged world of mining, where efficiency determines profitability, jaw crushers stand as the first line of defense against raw, unprocessed ore. From Australia’s iron-rich Pilbara region to Argentina’s…